Cement Production Line

Request a Quote

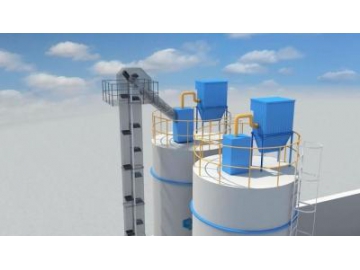

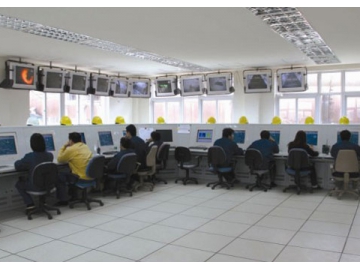

Our highly efficient cement production line uses advanced technology and equipment for cement making while still being affordable and cost-effective for small businesses. The production line features a five-stage cyclone pre-heater and CDC furnace system, a large output, and high classification efficiency. A computerized control system moves raw materials at the bottom of the blending hopper to the top of the cement silo in the dry rotary kiln process. Dust collectors are used at each step in the cement production line that generates dust to keep working conditions safe and to comply with environmentally-friendly regulations. Raw materials are also dried via exhaust heat from the kiln, saving energy.

Cement Making Process

1) Limestone crushing - Limestone Crusher

2) Raw material storage and blending - Hopper and Mixing

3) Raw material grinding - Ball Mill

4) Homogenizing of raw material and kiln feeding - Homogenizing Silo

5) Kiln inlet, kiln middle, kiln head and pulverized coal preparation - Rotary Kiln parts

6) Waste gas treatment at kiln inlet - Dust Collector

7) Clinker and admixture storage - Silo

8) Cement grinding - Cement Mill

9) Cement storage and packing - Cement Silo

Our Services

We offer a one-stop production line service for you, including designing, building, installing and servicing individual cement production line. Our cement making plants have a varying capacity of 300t/d, 500t/d, 1000t/d, and 1500t/d.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos