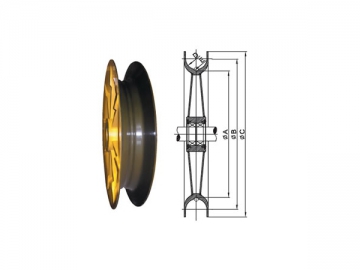

Wire Rope Sheaves

Wire rope sheaves and pulleys are used in lifting and transportation, port loading and unloading, mining machinery, metallurgy machinery, and other industries. They are known for their numerous advantages and outstanding wear resistance.

Pulley Categories: Hot rolled pulley, ring rolling pulley, wide groove pulley

Pulley diameter: 250 mm - 2000 mm

Wire line sizes: φ7.5mm-φ60mm

Safety factor: 4 times

Surface: Painting

l. Circular runout tolerance of diameter D – tl: 0≤tl≤D/1000 D: unit mm

2. Tolerance of bottom radius R – t2:

| R | t1 |

| ≤15 | 1.0 |

| >15 | 1.5 |

| Rim number | t3 |

| 1 | 2 |

| 2 | |

| 3 | 3 |

| 4 | |

| 5 | 4 |

| 6 | |

| 7 | 5 |

| 8 |

| D1 | t4 |

| ≤250 | -0.5 |

| >250-500 | -1.0 |

| >500-1000 | -1.5 |

| >1000-1200 | -2.0 |

| >1200-1500 | -2.5 |

| >1500-1800 | -3.0 |

| >1800-2000 | -3.5 |

5. Lateral runout tolerance of rope groove –t5: t5≤2D/l000 D: unit mm

6. Surface hardness of rope groove is HB—140~220, ring forged double disc pulley made of alloy, Surface hardness of rope groove is HRC≥40

- Ring forged double disc sheave

- Ring forged double disc sheave of groove with large width

Recommendation: suitable for the places of frequent utilization, and difficult replacement and maintenance areas

| Rope Diameter | Mooring Socket | Dimensions(mm) | ||||

| A | B | C | D | E | ||

| 16-17 | 4 | 560 | 694 | 750 | 60 | 9 |

| 18-19 | 4-5-6 | 630 | 788 | 850 | 70 | 10 |

| 20-21 | 5-6-7 | 710 | 880 | 960 | 75 | 11 |

| 22-24 | 6-7-8 | 710 | 890 | 970 | 80 | 12 |

| 25-27 | 7-8-9 | 800 | 984 | 1060 | 80 | 14 |

| 28-30 | 8-9-10 | 900 | 1116 | 1210 | 95 | 15 |

| 31-33 | 9-10-11 | 1000 | 1240 | 1360 | 105 | 17 |

| 34-36 | 10-11-12 | 1000 | 1240 | 1360 | 105 | 19 |

| 37-39 | 11-12-13 | 1200 | 1450 | 1560 | 110 | 20 |

| 40-42 | 12-13-14 | 1200 | 1450 | 1560 | 110 | 21 |

| 43 45 | 13-14-15 | 1400 | 1655 | 1760 | 110 | 23 |

| 46-48 | 14-15 | 1600 | 1870 | 1960 | 110 | 25 |

| 56 | 17 | 1800 | 2085 | 2200 | 122 | 29 |

| Item No | wire rope Diameter (mm) | Dimensions (mm) | recommend Bearing type | reference Weight (kg) | ||||||||

| D | D1 | R | b | w | f | D2 | D3 | B | ||||

| TH1201P | 10-14 | 280 | 325 | 7 | 37 | 28 | 8 | 55 | 63 | 64 | 221 | 12 |

| TH1202P | 60 | 69 | 66 | 212 | 12 | |||||||

| TH1203P | 65 | 75 | 68 | 213 | 13 | |||||||

| TH1204P | 70 | 80 | 70 | 214 | 13 | |||||||

| TH2201P | >14-19 | 355 | 415 | 10 | 50 | 38 | 8 | 80 | 90 | 74 | 216 | 22 |

| TH2202P | 85 | 96 | 78 | 217 | 23 | |||||||

| TH2203P | 90 | 102 | 82 | 218 | 24 | |||||||

| TH2204P | 95 | 108 | 86 | 219 | 27.5 | |||||||

| TH3201P | >19-23.5 | 450 | 521 | 12 | 60 | 46 | 10 | 95 | 108 | 90 | 219 | 38.5 |

| TH3202P | 100 | 113 | 94 | 220 | 39.5 | |||||||

| TH3203P | 110 | 124 | 102 | 222 | 42 | |||||||

| TH3204P | 120 | 135 | 106 | 224 | 43.5 | |||||||

| TH4201P | >23.5-30 | 560 | 650 | 15 | 73 | 57 | 10 | 130 | 146 | 106 | 226 | 69 |

| TH4202P | 140 | 158 | 110 | 228 | 72.5 | |||||||

| TH4203P | 150 | 170 | 116 | 230 | 76 | |||||||

| TH4204P | 160 | 180 | 122 | 232 | 78 | |||||||

| TH5201P | >30-37 | 710 | 822 | 19 | 92 | 72 | 12 | 160 | 188 | 128 | 42232 | 119 |

| TH5202P | 170 | 202 | 136 | 42234 | 123 | |||||||

| TH5203P | 180 | 212 | 136 | 42236 | 124 | |||||||

| TH5204P | 190 | 225 | 142 | 42238 | 129 | |||||||

| TH6201P | >37-43 | 800 | 926 | 22 | 104 | 82 | 12 | 160 | 188 | 128 | 42232 | 152 |

| TH6202P | 170 | 202 | 136 | 42234 | 157 | |||||||

| TH6203P | 180 | 212 | 136 | 42236 | 158 | |||||||

| TH6204P | 190 | 228 | 142 | 42238 | 163 | |||||||

| TH7201P | >43-50 | 900 | 1052 | 26 | 123 | 98 | 14 | 190 | 225 | 148 | 42238 | 278 |

| TH7202P | 200 | 235 | 154 | 42240 | 275 | |||||||

| TH7203P | 220 | 260 | 168 | 42244 | 305 | |||||||

| TH7204P | 240 | 278 | 182 | 42248 | 289 | |||||||

| TH8201P | >50-58 | 1120 | 1292 | 29 | 135 | 110 | 14 | 190 | 225 | 148 | 42238 | 385 |

| TH8202P | 200 | 235 | 154 | 42240 | 384 | |||||||

| TH8203P | 220 | 260 | 168 | 42244 | 417 | |||||||

| TH8204P | 240 | 278 | 182 | 42248 | 397 | |||||||

1. D0=D d2. The reference weight does not include the weight of bearing.

Parameters of Sheaves (Generally Sealed Type)| Item No | wire rope Diameter ( mm) | Dimensions ( mm ) | recommend Bearing type | reference Weight ( kg ) | ||||||||

| D | D1 | R | b | w | f | D2 | D3 | B | ||||

| TH1251P | 10-14 | 355 | 400 | 7 | 37 | 28 | 8 | 55 | 63 | 64 | 221 | 16 |

| TH1252P | 60 | 69 | 66 | 212 | 16 | |||||||

| TH1253P | 65 | 75 | 68 | 213 | 17 | |||||||

| TH1254P | 70 | 80 | 70 | 214 | 18 | |||||||

| TH2251P | >14-19 | 450 | 510 | 10 | 50 | 38 | 8 | 80 | 90 | 74 | 216 | 28 |

| TH2252P | 85 | 96 | 78 | 217 | 29 | |||||||

| TH2253P | 90 | 102 | 82 | 218 | 31 | |||||||

| TH2254P | 95 | 108 | 86 | 219 | 32 | |||||||

| TH3251P | >19-23.5 | 560 | 631 | 12 | 60 | 46 | 10 | 95 | 108 | 90 | 219 | 50 |

| TH3252P | 100 | 113 | 94 | 220 | 50 | |||||||

| TH3253P | 110 | 124 | 102 | 222 | 53 | |||||||

| TH3254P | 120 | 135 | 106 | 224 | 55 | |||||||

| TH4251P | >23.5-30 | 710 | 800 | 15 | 73 | 57 | 10 | 130 | 146 | 106 | 226 | 91 |

| TH4252P | 140 | 158 | 110 | 228 | 95 | |||||||

| TH4253P | 150 | 170 | 116 | 230 | 97 | |||||||

| TH4254P | 160 | 180 | 122 | 232 | 101 | |||||||

| TH5251P | >30-37 | 900 | 1012 | 19 | 92 | 72 | 12 | 160 | 188 | 128 | 42232 | 158 |

| TH5252P | 170 | 202 | 136 | 42234 | 163 | |||||||

| TH5253P | 180 | 212 | 136 | 42236 | 164 | |||||||

| TH5254P | 190 | 225 | 142 | 42238 | 168 | |||||||

| TH6251P | >37-43 | 1000 | 1126 | 22 | 104 | 82 | 12 | 160 | 188 | 128 | 42232 | 20 |

| TH6252P | 170 | 202 | 136 | 42234 | 208 | |||||||

| TH6253P | 180 | 212 | 136 | 42236 | 209 | |||||||

| TH6254P | 190 | 228 | 142 | 42238 | 213 | |||||||

| TH7251P | >43-50 | 1250 | 1402 | 26 | 123 | 98 | 14 | 190 | 225 | 148 | 42238 | 394 |

| TH7252P | 200 | 235 | 154 | 42240 | 394 | |||||||

| TH7253P | 220 | 260 | 168 | 42244 | 425 | |||||||

| TH7254P | 240 | 278 | 182 | 42248 | 406 | |||||||

| TH8251P | >50-58 | 1400 | 1572 | 29 | 135 | 110 | 14 | 190 | 225 | 148 | 42238 | 504 |

| TH8252P | 200 | 235 | 154 | 42240 | 503 | |||||||

| TH8253P | 220 | 260 | 168 | 42244 | 538 | |||||||

| TH8254P | 240 | 278 | 182 | 42248 | 519 | |||||||

Ordering Instructions

1. You can select the sheaves according to the rope diameter- d, nominal diameter of sheave - DO(D0=D d), bearing model, working environment(generally sealed type or strictly sealed type(A type)) in the table.(table 1-4 for generally sealed type, table 5-8 for strictly sealed type )

2. Customization is available in our factory. We can manufacture the sheaves according to the steel cable end.

3. We can design and manufacture special sheaves and pulley blocks.

Other search items: sheaves& pulleys, pulley sheaves/wheels, pulley block sheave