Impeller Valve Bag Filler

Automatic valve bag filling machine with ultrasonic sealer

- Large valve bags (10-50 kg)

- Packaging speed 180-400 bags per hour

Our impeller valve bag fillers can efficiently handle the packaging of abrasive powder and granular materials into valve bags ranging from 10 to 50 kg. Equipped with ultrasonic sealing technology, these bag fillers ensure bags are securely sealed with high accuracy and speed. It seamlessly combines electronic weighing, automatic bag releasing, and effective dust removal into one fully automated solution, simplifying the packing process and improving productivity. The valve bag fillers are also adjustable, allowing flexible customization according to specific operational requirements.

Ideal for packaging materials such as putty powder, gypsum powder, and other powdered construction products.

| Air consumption | 10m³/h |

| Dust removal air volume | 2000m³/h |

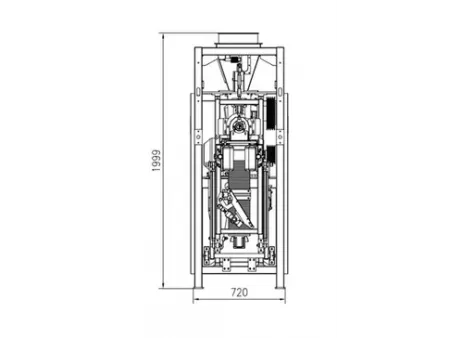

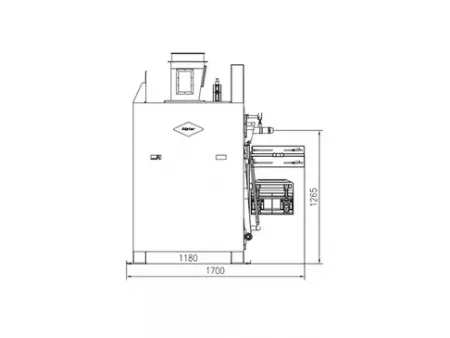

| Dimensions | 2118(1850)×1030×720mm |

| Packaging accuracy | ≤1% (25kg) |

| Bag weight | 10-50kg |

| Class of protection | ≥IP54 |

| Applicable bag size | 320-600mm |

| Packaging speed | 180-400bag/hour |

| Sealing method | None/Ultrasonic |

| Applicable bag type | Paper bag, PE/PP valve bag, paper-plastic composite valve bag |

| Power | 6000 2600W |

| Voltage | 380V |

| Air pressure | ≥0.6Mpa |

| Rated current | 2A |

| Weight | 620kg |

- Fitted with a built-in dust collection system to keep the workspace clean by efficiently capturing dust during filling.

- User-friendly automated controls reduce manual operations and increase overall productivity.

- Minimal compressed air consumption ensures bags are uniformly filled without wastage.

- The robust motor supports smooth and consistent material flow, simplifying the packaging process.

- Quick-release impeller housing simplifies maintenance and cleaning tasks.

- Wear-resistant impeller components ensure long-lasting performance even with abrasive materials.

Nippon Paint (China) Co., Ltd.

Industry: Chemical raw materials & chemical products manufacturing