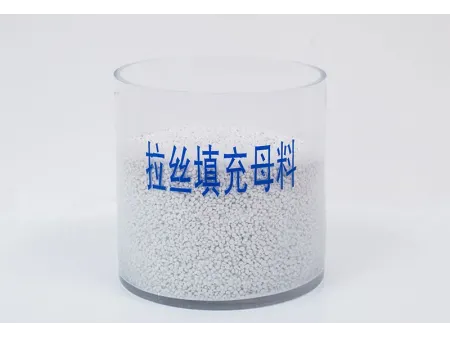

PE Filler Masterbatch for Woven Bag, JH-206A

To tackle common production issues like poor whiteness, dust generation, and uneven dispersion in woven bag manufacturing, Jinghua has developed this specialized filler masterbatch. Made with PE carrier resin and ultra-fine inorganic powders, this masterbatch is non-toxic, odorless, and is formulated to improve the strength, flowability, and overall quality of polypropylene woven bags and jumbo bags. This masterbatch is ideal for polypropylene woven bags and jumbo bags, providing enhanced durability, excellent dispersion, and smoother processing. Additionally, it helps manufacturers produce bags that are not only durable but also cost-efficient, thanks to its high filler content that lowers material usage without sacrificing product performance.

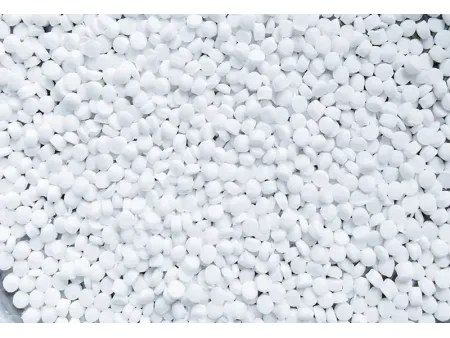

- Appearance: white granules

- Granule Size: ∅3×4mm

- Melting flow index: 3-20g/min (customizable)

- Whiteness: ≥85%

- Density: 1.6-1.8g/cm³

- Moisture & Volatile Matter: ≤0.3%

- Dispersibility: no solid granules

- The masterbatch is non-toxic and odorless, ensuring it is safe for industrial use and maintaining a clean working environment

- With a high filler content, it enhances production efficiency by providing excellent flowability, preventing machine clogging even at higher concentrations

- It offers low moisture content and high whiteness, which results in bright, clean-looking woven bags while also improving their aesthetic and functional qualities

- Enhances the strength and durability of woven bags by ensuring uniform dispersion throughout the material, leading to consistent quality and reliability

- Cost efficiency is achieved by reducing the amount of raw materials needed, helping manufacturers lower production costs without compromising product performance

PE filler masterbatch is widely used in producing woven bags for fertilizers, feeds, cement packaging, and export goods, as well as jumbo-sized woven bags. It enhances the strength and durability of polypropylene woven products, offering a cost-effective solution that maintains product quality while significantly reducing raw material expenses.

- 25kg bags with PE waterproof lining

- Jumbo bags