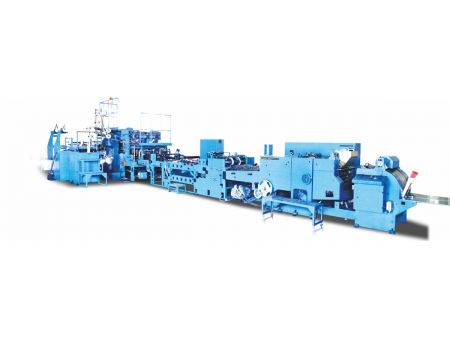

SBH35F-HD Fully Automatic Sheet Fed Twisted Handle Paper Bag Machine

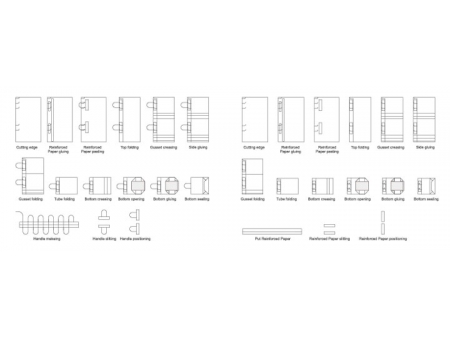

The fully automatic sheet fed paper handle bag machine uses sheet paper, reel reinforced paper and paper twist rope as the raw material, and carries out paper handle manufacturing. handle patching, top folding, tube forming, gusset forming, bottom forming, compaction output or stick reinforced paper, top folding, tube forming, gusset forming, punch eyelets, bottom pasting, and compaction output in one continuous process. This machine is also ideal for producing two different types of shopping bag type production, making it suitable for clothing, footwear, sports brand or luxury brands products outside of the bag production. It is fully automatic, and capable of processing various paper types, including kraft paper, coated paper, and ivory board (including laminated paper).

-

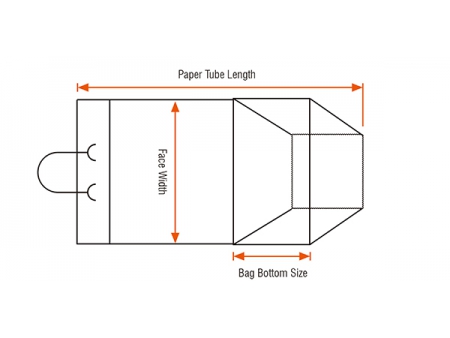

Model:

SBH35F-HD - Paper Thickness (gsm):

- 100-190

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 180-330

- Bag Bottom Size (mm):

- 70-150

- Max. Speed (bags/min):

- 70

-

Model:

SBH45F-HD - Paper Thickness (gsm):

- 100-200

- Tube Cut Off Length (mm):

- 300-560

- Bag Face Width (mm):

- 220-450

- Bag Bottom Size (mm):

- 70-170

- Max. Speed (bags/min):

- 70

-

Model:

SBH35F - Paper Thickness (gsm):

- 90-190

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 180-350

- Bag Bottom Size (mm):

- 70-160

- Max. Speed (bags/min):

- 70

-

Model:

SBH45F - Paper Thickness (gsm):

- 100-200

- Tube Cut Off Length (mm):

- 300-560

- Bag Face Width (mm):

- 220-450

- Bag Bottom Size (mm):

- 70-170

- Max. Speed (bags/min):

- 70

| Technical Info | | | | |

| Sheet Width (mm) | 530-1050 | 610-1260 | 530-1050 | 610-1260 |

| Sheet Length (mm) | 350-600 | 380-620 | 350-600 | 380-620 |

| Paper Thickness (gsm) | 90-190 | 100-200 | 90-190 | 100-200 |

| Bag Face Width (mm) | 180-350 | 220-450 | 180-350 | 220-450 |

| Tube Length (mm) | 280-540 | 300-560 | 280-540 | 300-560 |

| Bag Bottom Size (mm) | 70-160 | 70-170 | 70-160 | 70-170 |

| Bag Mouth Fold Width (mm) | 40-60 | 40-60 | / | / |

| Handle paper cut Length (mm) | 152.4 | 188.4 | / | / |

| Handle paper width (mm) | 90-100 | 90-100 | / | / |

| String Height (mm) | 170-185 | 170-185 | / | / |

| String Pitch (mm) | 76.2 | 94.2 | / | / |

| Max. Speed (bags/min) | 70 | 70 | 70 | 70 |

| Total Power (kW) | 27 | 30 | 27 | 30 |

| Machine Size ((L×W×H)m) | 15×2.71×2.05 | 15×2.32×2.05 | 12.5×1.64×1.52 | 12.56×2.12×1.52 |

| Handle Making machine ((L×W×H)m) | 5.5×1.35×2.7 | 5.4×1.34×2.69 | / | / |

- Handle feeding unit: Mechanical automatic tension adjustment, automatic adjustment of handle position, equipped with an automatic web guide system.

- Front and Side Guide unit: Every sheet is accurately positioned by the alignment guide, which ensures the uniformity of every batch.

- Automatic Creasing and Punching unit: Automatic creasing and punching, two kinds of shopping bag production processes is in one machine. (handle or no handle)

- Automatic Collection Unit: Automatic counting processes makes it easy to collect finished bags