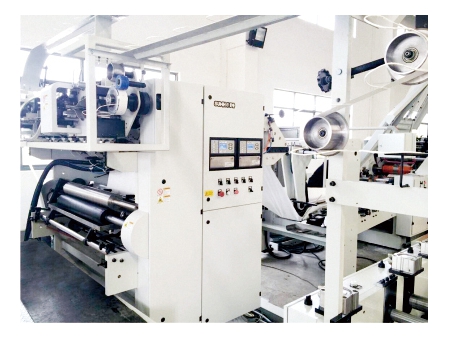

SBH550T/550TB-HD Automatic Roll Fed Twisted Handle Paper Bag Machine

Request a Quote

This machine is designed for producing square-bottom paper bags with twisted handles, utilizing materials such as paper roll, paper patch roll, and paper rope. It encompasses a fully automated process comprising handle fabrication, handle attachment, tube formation, tube cutting, and bottom forming. This design is particularly ideal for packaging in the food, apparel, and luxury brand sectors.

Twisted Handle Unit

Bag Schematic Diagram

Specifications

-

Model:

SBH550T-6HD - Paper Thickness (gsm):

- 80-150

- Tube Cut Off Length (mm):

- 360-650; 360-770(★)

- Bag Face Width (mm):

- 230-540; 220-540(★)

- Bag Bottom Size (mm):

- 80-230

- Max. Speed (bags/min):

- 120

-

Model:

SBH550TB-6HD - Paper Thickness (gsm):

- 80-150

- Tube Cut Off Length (mm):

- 360-650; 360-770(★)

- Bag Face Width (mm):

- 230-540; 220-540(★)

- Bag Bottom Size (mm):

- 100-280

- Max. Speed (bags/min):

- 120

| Model | | |

| Paper Roll Width (mm) | 650-1510 | 690-1510 |

| 630-1510(★) | 670-1510(★) | |

| Paper Roll Dia. (mm) | ≤1500 | ≤1500 |

| Paper Roll Core Dia. (mm) | Ø76 | Ø76 |

| Paper Thickness (gsm) | 80-150 | 80-150 |

| Tube Cut Off Length (mm) | 360-650 | 360-650 |

| 360-770(★) | 360-770(★) | |

| Bag Face Width (mm) | 230-540 | 230-540 |

| 220-540(★) | 220-540(★) | |

| Bag Bottom Size (mm) | 80-230 | 100-280 |

| Handle Rope Height (A) (mm) | 115/125/140/150 | 115/125/140/150 |

| Handle Patching Length (C) (mm) | 190.5 | 190.5 |

| Handle Patching Width (B) (mm) | 40-50 | 40-50 |

| Rope Pitch (D) (mm) | 95 | 95 |

| Handle Rope Diameter (mm) | Ø3-4.5 | Ø3-4.5 |

| Handle Paper Patch Roll Diameter (mm) | Ø1200 | Ø1200 |

| Handle Paper Patch Roll Width (mm) | 80-100 | 80-100 |

| Handle Paper Patch Thickness (gsm) | 90-135 | 90-135 |

| Max. Speed (bags/min) | 120 | 120 |

| Total Power (kW) | 37.2 | 37.2 |

| Machine Weight (kg) | approx. 20500 | approx. 20500 |

| Machine Size ((L×W×H) (m) | 16.2×6×3.4 | 16.2×6×3.4 |

| Three Types of Bottom Seal | yes (one) | yes (one) |

| Servo Lip Cut Device | no | no |

| 1-4 Colors Flexo Printing Unit | yes | yes |

| Servo Patching Unit | yes | yes |

Note: "★" stands for No Handle.

Features

- Features a servo-adjustable former for automatic adjustments of face width and side gussets, significantly reducing setup time for different bag specifications.

- Includes a vacuum-assisted drum for enhanced control during the bag making process.

- Utilizes a Mitsubishi electric control system and motion controller (CPU) for high-speed and precise motion control, with an touch screen display for clear operational functionality.

- Equipped with a German BST automatic web guiding system to minimize waste and enhance efficiency.

- Features an American NORDSON cold glue adhesive system for bag side sealing, with automatic glue volume adjustment based on operation speed, and an auto-cleaning and recycling system to prevent glue wastage.

- The handle making unit incorporates both NORDSON cold and hot glue systems, optimizing production for both economy and efficiency.

- Comes with an automatic lubricating system for maintenance-free operation.