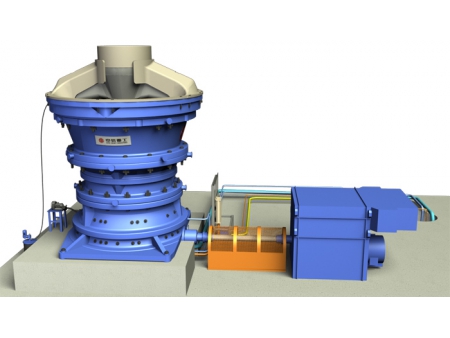

Gyratory Crusher

The PXZ series gyratory crushers are designed for primary crushing applications, with models capable of handling capacities from 1000 to 17000 tons per hour. These crushers are characterized by their high throughput, high crushing efficiency, large reduction ratio, uniform product size, low power consumption, and even wear within the crushing chamber. The latest generation incorporates advanced technologies such as a high swing speed of the main shaft, resulting in a 25%-40% higher processing capacity compared to similar models from other manufacturers, along with superior discharge particle size and energy savings of approximately 20%-30%, as proven in numerous operational sites.

- Restart with load capability: Easily restarts even when the crushing chamber is fully blocked with material.

- Integral forged main shaft: The main shaft and mantle are integrated into a single forging, eliminating the risk of main shaft fracture and extending service life.

- Advanced spider bearing technology: Utilizes spherical bearings in the spider to ensure flexible swing of the mantle and improved crushing performance.

- Integral high-arch spider structure: The spider arm and ring are a single casting, fully guaranteeing the spider's strength and allowing for a larger feed particle size.

- Direct motor-main body connection: The main motor is directly coupled to the crusher body and equipped with a hydraulic safety coupling featuring flexible torque protection adjustment.

- External gear adjustment device: Allows for convenient adjustment of the gear backlash.

- Efficient maintenance equipment: Equipped with professional electric maintenance carts and hydraulic lifting platforms, increasing maintenance efficiency by over 200% compared to traditional manual methods.

| Model | Feed opening (mm) | Open side setting (mm) | Mantle bottom diameter (mm) | Max. motor power (kW) | Capacity (t/h) |

| | 780 | 110-150 | 1420 | 300 | 700-1500 |

| | 1100 | 140-175 | 1650 | 450 | 1800-2850 |

| | 1270 | 150-175 | 1650 | 500 | 2200-2950 |

| | 1375 | 150-200 | 1910 | 650 | 2620-3470 |

| | 1600 | 150-200 | 1910 | 710 | 2670-5800 |

| | 1525 | 160-230 | 2260 | 750 | 4200-7210 |

| | 1780 | 160-230 | 2260 | 800 | 4800-8600 |

| | 1525 | 160-260 | 2870 | 1200 | 5430-11000 |

| | 1600 | 175-280 | 3300 | 1500 | 7500-12400 |

| | 1830 | 175-280 | 3300 | 1800 | 8600-15000 |

Note1: Actual production capacity depends on the actual processing circuit and ore properties. The capacity values above are calculated based on a bulk density of 1.6t/m³ and medium hardness ores.

Note2: The above parameters are for reference only and are subject to detailed engineering.

- Name of Client: Vale

- Project: Conceicao

- Location: Brazil

- Crusher Model: PXZ60-89

- Material: Iron

- Capacity: 30 million tons / year

- Year of Manufacture: 2010

- Name of Client: LKAB

- Project: Mertain Mine

- Location: Sweden

- Crusher Model: PXZ62-75

- Material: Iron

- Capacity: 15 million tons / year

- Year of Manufacture: 2013

- Name of Client: Sinoma

- Project: Dapaikuang Project

- Location: China

- Crusher Model: PXZ60-89Ⅲ

- Material: Granite

- Capacity: 30 million tons / year

- Year of Manufacture: 2022

- Name of Client: Zijin Mining Group

- Project: Duobaoshan Copper Mine

- Location: China

- Crusher Model: PXZ62-75

- Material: Copper

- Capacity: 25 million tons / year

- Year of Manufacture: 2017

- Name of Client: Shandong Gold Group

- Project: Ghana Namdini Gold Project

- Location: Ghana

- Crusher Model: PXZ54-75

- Material: Gold

- Capacity: 10 million tons / year

- Year of Manufacture: 2023

- Name of Client: Jinduicheng Molybdenum

- Project: Ruyang Jinduicheng

- Location: China

- Crusher Model: PXZ54-75

- Material: Molybdenum

- Capacity: 10 million tons / year

- Year of Manufacture: 2015

- Name of Client: Gerald Group

- Project: Marampa Project

- Location: Sierra Leone

- Crusher Model: PXZ50-65Ⅲ

- Material: Iron

- Capacity: 12 million tons / year

- Year of Manufacture: 2022

- Manufacturing

Casting and Forging Capacity

We have four production lines that have the capacity to produce large steel castings, large high-value forgings, large annular parts and large non-ferrous metal parts respectively. - Service

Lifetime service

With state-of-the-art technology and rich experience, CITIC HIC works through each critical step to individualize the optimal process and performance as per customer needs. Our lifetime service covers equipment installation, testing, maintenance, refurbishing, remote monitoring & diagnosis, upgrading & retrofitting, and performance guarantee.