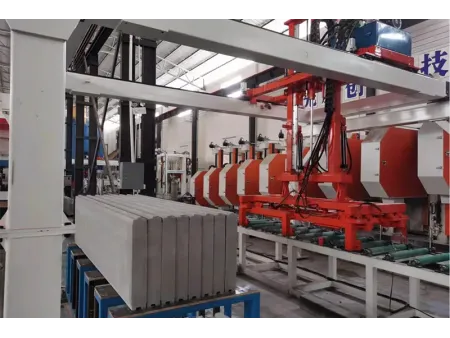

Lifting & Stacking Machine

Lifting clamps and stacking machines for concrete blocks & wall panels

The lifting and stacking machine is an intelligent device designed for stacking and organizing concrete blocks and wall panels. It automates the packaging, storing, and handling of finished products on the production line, providing a fast, accurate, and reliable alternative to manual labor. There are two types available: ordinary stacking machines and large stacking machines.

The concrete block stacker, also known as a block cuber, is mainly used for handling and transferring bricks. It saves manpower and improves production efficiency, commonly used in the building materials production industry.

Specifications

- Dimensions: 4800×3300×4500mm

- Power: 12kW

- Stacking speed: 25m³/h

Features

- High efficiency: the concrete block stacker is designed with precision and flexibility, allowing accurate grabbing, handling, and placing of bricks.

- Ease of operation: made of durable materials and precisely designed, the concrete block stacker is easy and quick to use.

- Labor-saving: the concrete block stacker reduces manual handling, saving labor costs.

- Good stability: the concrete block stacker features anti-fall characteristics with strong and stable clamping force, ensuring bricks do not fall.

The wall panel stacking machine is a device specifically designed for handling and stacking wall panels, enhancing production efficiency.

Specifications

- Dimensions: 4800×3300×4500mm

- Power: 12kW

- Stacking speed: 25m³/h

Features

- High efficiency: it is capable of handling a large number of wall panels in a short time.

- Stability: the wall panel stacker can stably grab and secure wall panels without damaging their surface.

- Flexibility: suitable for wall panels of different sizes and thicknesses.

- Low cost: using the wall panel stacker can reduce manual labor, lowering labor costs.

Also known as the mini stacking machine, it is mainly used for handling and stacking bricks, working in conjunction with a forklift.

Specifications

- Dimensions (L×W×H): 1.2×1.2×1.4m

- Speed: 20m³/hour

- Usage: mechanically operated, working with forklift truck

Features

- Low cost: economical to use.

- Easy operation: simple to operate and convenient to move.

- Automatic clamping: the clamp automatically tightens to lift the concrete cake when the forklift raises it and opens when the cake lowered.

It is mainly used for the automatic handling and multi-layer stacking of bricks, with numerically controlled cyclic operations. Packaging without pallets requires an accompanying strapping machine.

Specifications

- Dimensions: 4800×2900×4800mm

- Power: 12kW

- Stacking speed: 50m³/h (packaging with pallets), 40m³/h (packaging without pallets)

Features

- High efficiency: replaces manual stacking, completing automatic stacking during production efficiently.

- Precision: equipped with high-precision positioning function, able to place blocks accurately in the predetermined position.

- Reliability: uses advanced mechanical, electronic, and control systems for good durability and stability.

- Safety: equipped with safety protection devices to stop operation in abnormal situations, ensuring personnel safety.

- Labor-saving: reduces a large amount of manual labor, lowering costs.

- Numerically controlled: utilizes programmable settings to adjust speeds, ensuring it can handle diverse production and packaging demands efficiently.