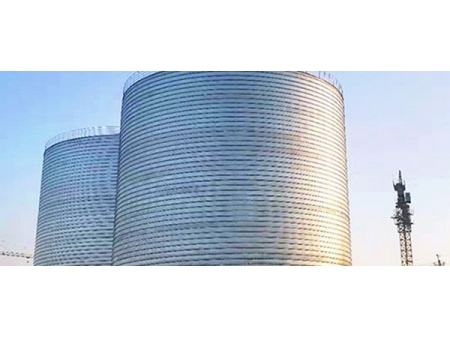

Spiral Silos

The spiral steel silos made by our spiral silo making machine can fulfill your versatile storage demands, accommodating granular, solid, powdered, and liquid materials with ease. There are also a myriad of benefits for the spiral silos made by our spiral silo making machine:

- Lightweight construction

- Small footprint

- Cost-effectiveness

- Fast and safe construction

- Superior sealing

- A wide range of material storage options.

When it comes to complete spiral silo solutions, Zhongxing are the partner you can always count on. Our offerings cover both flat-bottom and hopper-bottom silos, ensuring that you have all the essentials from beginning to end.

- Flat Bottom Silos

- Hopper Bottom Silos

The Optimal Configuration for the Diameter and Height of Spiral Silos

(Ø - diameter, H - height, not mandatory ranges, can be configured based on process design requirements, unit is meter).

| H6 | H8 | H10 | H12 | H14 | H16 | H18 | H20 | H22 | H24 | H26 | H28 | H30 | |

| Φ3 | |||||||||||||

| Φ5 | |||||||||||||

| Φ7 | |||||||||||||

| Φ9 | |||||||||||||

| Φ11 | |||||||||||||

| Φ13 | |||||||||||||

| Φ15 | |||||||||||||

| Φ17 | |||||||||||||

| Φ19 | |||||||||||||

| Φ21 | |||||||||||||

| Φ23 | |||||||||||||

| Φ25 | |||||||||||||

| Φ27 | |||||||||||||

| Φ29 | |||||||||||||

| Φ31 |

- Agricultural industry: grain storage silos, oil silos, feed silos

- Pharmaceutical industry: pharma storage tanks

- Brewing industry: wine storage tanks

- Construction industry: aggregate silos, cement silos, fly ash silos, gypsum powder storage silos

- Environmental protection industry: wastewater storage tank

- Other industries: steel desulfurization storage silos, natural gas storage silos, fire water tanks and so on

- Industrial Material: cement, GGBS, fly ash, calcium carbonate, ash, plastic pellets, lime, sand, gypsum, carbon black, PVC, coal, coal dust, marble powder etc.

- Food Materials: flour, seeds, chickpeas, beans, sesame, almonds, grain cereals, corn, starch, spices, and more.

- Exceptional performance and long service life

Five times the thickness of the parent metal at the spiral double fold joints significantly enhances load-bearing capacity. Thanks to the characteristics, spiral silo made by our spiral silo making machine features superior structural stability, strength, and cost-effectiveness, permitting an longer lifespan compared to other steel silos. - Excellent airtightness and versatility

With meticulous precision, spiral silos made by our spiral silo machine offer impeccable sealing performance. They can store a wide range of products, including solids, granules, powders, and liquids. Ideal for grain storage, those spiral silos shield internal materials from external humidity and meet requirements for hermetic pest control and fumigation. - Fast silo construction and cost-effectiveness

These spiral silos made by our silo machine weigh only 1/6 of concrete silos with the same volume, significantly reducing foundation costs. With an incredibly fast silo construction (around 5 days for a 1000-ton silo), you'll save both time and money. - Small footprint and easy management

One of the key advantages of spiral silos is their flexibility in height and diameter selection. With a minimum silo spacing of just 50cm, they require minimal land, making them highly adaptable to various settings.

Our company has harnessed advanced modern silo construction techniques to bring you a truly unique and efficient building process. During construction, we start by feeding 495mm (625, 750mm) wide steel strips unrolled by uncoiling unit into the forming machine, which transforms the steel strips into the precise geometric shapes needed. Then, through double folding machine, the adjoining edges of steel strips are seamlessly locked together, forming a continuous spiral rib, 28-50mm wide, that spirals around the exterior of the silo. This not only adds to the structural integrity but also enhances the overall strength of the silo. When it comes to materials of different compositions, our spiral silo making machine has you covered with double folding and bending capabilities.

Besides, our technological prowess also embodies in the construction processes. On-site silo construction and the silo roof can be installed on the ground. Thus there's no need for towering scaffolds or extensive auxiliary facilities. Our spiral silo making machine operates at a blistering speed of 3-6 meters per minute for shaping and bending, ensuring exceptionally short construction timelines.

Further, our silos are exclusively crafted from 2.5-6.0mm coils, making them incredibly light in weight. In fact, their weight is equivalent to the reinforcing steel used in concrete silos of the same capacity. Therefore, the silos made by our spiral silo making machine have significantly reduced construction costs without compromising on strength.

| Type | Concrete silos | Welded silos | Spiral silos | Assembly silos |

| Scope of application | <0.9 | <1 | 1 | <0.8 (specific for grain industry) |

| Weight | >1.1 | >1 | 1 | <1 |

| Footprint | >1 | 1 | 1 | 1 |

| Construction Period | >1.1 | >1 | 1 | 1 |

| Material Consumption and Costs | >1.1 | >1 | 1 | <1 |

| Construction Expenses | >1.1 | >1 | 1 | <1 |

| Construction Safety Hazards | >1.1 | ≥1 | 1 | 1 |

| Sealing Performance | <1 | 1 | 1 | incapacity |

| Maintenance Difficulty | >1.1 | >1 | 1 | >1 |

The values in the table are not specific measured values, they are for visual representation and reference only.

We primarily provide spiral steel silo solutions for customers worldwide. In addition, we can also offer assembly silos, welded silos and steel silos with other structural types.