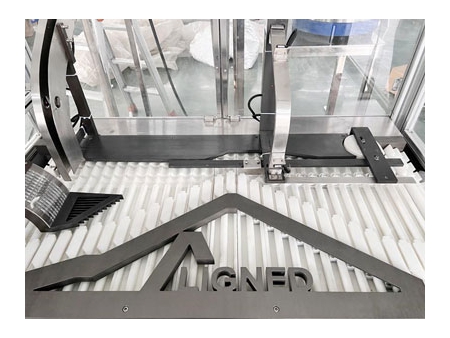

Automatic Effervescent Tablet Filling Machine

KXZ-130B

The straight tube tablet filling machine has high output, stable performance and fully automatic operation. When there is no tablet, no bottle, no cap, etc., it will automatically alarm and stop. It is the most ideal pharmaceutical equipment for packaging effervescent tablets in pharmaceutical factories, health care products factories, food factories and similar packaging.

| Max. Output | 120tube/min |

| Max. Tablet Feeding Speed | 98000pcs/h |

| Tablet Diameter (minimum-maximum), in Millimeters | 16-33mm |

| Tablet Thickness | 3-12mm |

| Tablet Hardness | ≥40N |

| Bottling Quantity | 5-20pcs |

| Tube Length | 60-200mm |

| Tube Diameter | 18-35mm |

| Power Supply | 380V 50Hz 3P |

| Power | 4.5kW |

| Overall Size | 2452mm*1206mm*1991mm |

| Weight | About 715kg |

- The tablet filling machine utilizes dual photocell detection to ensure that neither tubes nor tablets are missing or damaged, significantly increasing the quality of the final products.

- Its newly designed structure significantly reduces the space required, making it an ideal solution for facilities with limited space.

- This machine delivers tablets more than twice as fast as traditional methods. Its smooth and consistent feeding mechanism helps avoid tablet clogging and reduces material waste.

- It features a system that allows mold changes to accommodate different tube sizes within just two minutes, drastically improving production efficiency.

- Easy to operate thanks to a dual-button start system—one button ensures the feed is correctly positioned, and another starts the automatic operation of the machine.

- Optional humidity detection and an alarm system can be integrated to monitor and maintain the ideal conditions, safeguarding the integrity of the tablets.

- This machine can be connected to a labeling machine and managed with the same control system, which reduces the frequency of operations and enhances efficiency.

- The filling machine achieves a stable output of 120 tubes per minute, a 70% increase in production compared to traditional equipment.

- The entire set of equipment can be shipped disassembled and easily reassembled with bolts on-site, making the installation process straightforward and convenient.

The effervescent tablet filling machine efficiently load tablets into tubes, ensuring precise dosing and stable product quality. It features an advanced automation system that enhances both reliability and performance. In instances where there is a shortage of tablets, bottles, or caps, the machine is programmed to automatically issue an alert and halt production. This proactive approach prevents errors and maintains continuous quality control.

The automated functions of the machine include a cap feeder, a tablet feeder, and a bottle feeder, all of which simplify the overall filling process. These components work in harmony to provide a seamless operation, from the initial placement of tablets into bottles to the final step of securing the caps. This integration not only boosts efficiency but also ensures that each unit produced meets high standards of quality and consistency.

- Cap feeder: Vibrating plate is used to automatically unscramble the caps and adjust the direction to feed them into the capping station in an automatic manner.

- Tablet feeder: Vibrating plate is equipped to automatically unscramble the tablets and feed them into the bottling mechanism.

- Bottle feeder: Automatically unscramble the bottles and send them to the bottling mechanism.

- Bottling mechanism: Automatically count and arrange the tablets into each track and send them into the bottle.

- Capping mechanism: When a bottle and tablet are detected, the cap is automatically pressed into the bottle.