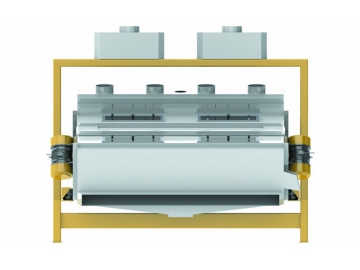

High density cleaner

Features

1. The high consistency cleaner operates without need for a motor

2. Wear-resistant cone

3. Removes heavy impurities

4. National patent no.: 200730017299.2

5. Simple structure, small footprint, large capacity, easy to operate

6. High purification efficiency

7. The pulp passes through the cleaning device without tail plasma processing equipment

8. Zero fiber loss, cone wear, long life, no drive, no power, installed in the slurry transport process can achieve an excellent deslagging effect

10. Cone body is made from alumina wear resistant ceramic, ensuring a long life.

11. Two-cone structure reduces fiber loss while raising the heavy impurity separation efficiency.

12. Controlled by PLC system.

1. The high consistency cleaner operates without need for a motor

2. Wear-resistant cone

3. Removes heavy impurities

4. National patent no.: 200730017299.2

5. Simple structure, small footprint, large capacity, easy to operate

6. High purification efficiency

7. The pulp passes through the cleaning device without tail plasma processing equipment

8. Zero fiber loss, cone wear, long life, no drive, no power, installed in the slurry transport process can achieve an excellent deslagging effect

10. Cone body is made from alumina wear resistant ceramic, ensuring a long life.

11. Two-cone structure reduces fiber loss while raising the heavy impurity separation efficiency.

12. Controlled by PLC system.

- Finished products in workshop

- Semi-finished products in workshop

Application

The machine is used to remove heavy rejects, like sands, iron, and so on in the pulping stage in pulp and paper making plants.

| Model | Capacity (t/d) | Consistency (%) | Inlet pressure (mpa) | Outlet pressure (mpa) | Rinse water pressure (mpa) | Capacity (m3/min) | Inlet diameter (mm) | Outlet diameter (mm) |

| 10-20 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 0.8-0.9 | φ150 | φ80 | |

| 20-30 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 1.0-1.2 | φ175 | φ100 | |

| 30-45 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 1.3-1.5 | φ200 | φ125 | |

| 45-60 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 1.5-2.0 | φ225 | φ150 | |

| 69-75 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 2.0-2.5 | φ250 | φ150 | |

| 75-110 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 2.5-3.0 | φ250 | φ165 | |

| 100-140 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 3.0-3.5 | φ250 | φ180 | |

| 140-260 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 3.5-4.0 | φ250 | φ200 | |

| 200-400 | 0.8-6 | 0.15-0.35 | 0.1-0.3 | Inlet pressure 0.2 | 4.0-6.0 | φ300 | φ273 |