F375B Medium Mooney Bisphenol Copolymer Precompound, Hardness 77

Request a Quote

Data Sheet

- Material Type: Medium viscosity incorporated cure fluoroelastomer precompound with bisphenol curing

- Features: Excellent metal bonding performance and adhesive flow, suitable for transfer molding and compression molding

- Applications: Oil seals, bearing shims, and other compression-molded components

- Working Temperature Range: Maximum 230℃ and minimum -17℃

- Lab Testing Curing Condition:

Primary cure: 177℃ × 6min

Post cure: 230℃ × 16h

Original Properties

| Property | Unit | Test Method | Typical Value |

| Fluorine Content | % | -- | 66 |

| Specific Gravity | g/cm³ | ASTM D297 | 1.82 |

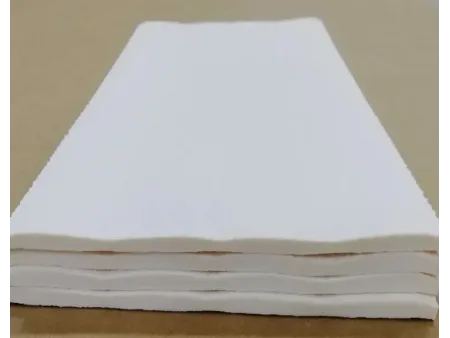

| Color | -- | -- | White |

| Solubility | -- | -- | Ketones and esters |

| Mooney Viscosity ML (1 10@121℃) | Mu | ASTM D1646 | 34 |

Test Formulation

| Formulation | Phr | Grade |

| F375B | 100 | F375B |

| MgO | 3 | MgO 150# |

| Ca(OH)2 | 6 | NICC 5000 |

| N990/MT N990 | 30 | Thermax® N990 |

Rheological Properties

| MDR 100cpm, 0.5°Arc, 6 minutes, 177°C | ||

| Property | Unit | Typical Value |

| ML, Minimum Torque | N.M | 0.13 |

| MH, Maximum Torque | N.M | 1.93 |

| Scorch Time (ts₂) | -- | 1’12 |

| Cure Time (tc90) | -- | 2’35 |

Mechanical Properties

| Property | Unit | Test Method | Typical Value |

| Hardness (Shore A) | pt | ASTM D2240 | 77 |

| Tensile Strength | MPa | ASTM D412 | 14.60 |

| Modulus 100% | % | ASTM D412 | 5.3 |

| Elongation at Break | % | ASTM D412 | 245 |

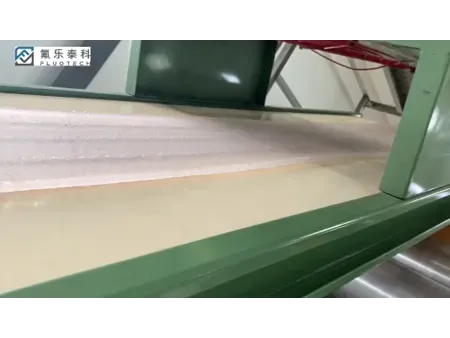

Manufacturing Process