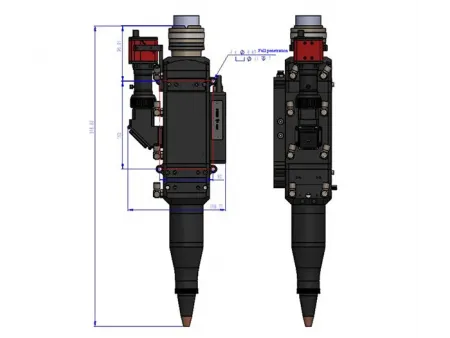

15kW Laser Welding Head with Temperature Monitoring

LWT15A0

Fiber laser welding head with temperature control for processing various metals with power ratings of up to 15kW

LWT15A0

Fiber laser welding head with temperature control for processing various metals with power ratings of up to 15kW

The laser welding head is designed with an intelligent temperature monitoring and early warning system to enhance reliability during high-power welding. Its contamination detection function provides timely alerts, while collision protection ensures rapid recovery after accidental impact. A fully water-cooled body maintains effective temperature reduction, enabling long-term stable operation. The laser welding head with temperature control can also be expanded to support MIG welding, making it adaptable to more complex processing requirements and further improving welding efficiency.

| Model | LWT15A0 |

| Rated Power | 15kW |

| Wavelength | 1080±10nm |

| Collimation Length | 100mm/150mm |

| Focal Length | 150mm/200mm/250mm/300mm/400mm |

| Blowing Method | Coaxial/paraxial |

| Auxiliary Gas Pressure | ≤1MPa |

| Weight | 4.6kg |

This temperature monitoring welding head is suitable for high-power welding up to 15kW. It can process stainless steel, carbon steel, copper, and aluminum alloys with consistent quality and precision.

Provides early warnings to remind operators to replace lenses and automatically shuts down in case of serious contamination, preventing poor welds and protecting the welding head.

Coaxial / air knife blowing assembly safeguards against damage, enabling non-destructive collisions and rapid recovery

Full-body water-cooling system ensures long-term stable performance

Delivers stronger welds while reducing material consumption and improving overall welding efficiency.