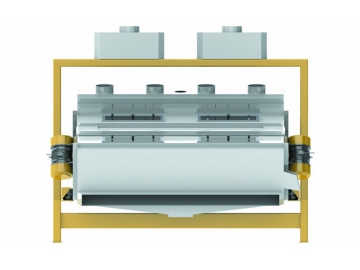

Low Density Cleaner, 606 Series

Capacity: 230~270L/min

Huaxia's 606 series low density cleaner is great for pulping and detrashing systems. This particular detrashing equipment is primarily used to remove light impurities from different types of paper pulp under high stock consistency, especially light impurities found in secondary fibers, such as plastic sheets, hot melt materials, wax, goo, ink particles and more. In addition, this low density pulp cleaner can remove free or slightly combined air in the paper pulp.

Our single low density cleaner boasts a large production capacity and is a leader on the Chinese market. This allows the number of cleaners in the pulping system to be reduced, and the stock cleaner offers a stable operation, high reliability, and cost efficiency.

Working Principle

The pulp cleaner comes with a high efficiency, due to its unique design. During the downward spiral movement of the pulp, fibers will be thrown to the inner wall under centrifugal force and drained from the purified pulp outlet, while the light impurities will gather in the central area of the cone, and then discharged through a pipe from the bottom.

| Capacity | 230~270L/min |

| Inlet pressure | 0.20~0.30mpa |

| Single stage volume slag rate | 10~14% |

| Inlet consistency | 0.4~1.0% |

| Outlet pressure | 0.08~0.15Mpa |

| Single stage solid slag rate | 5~8% |