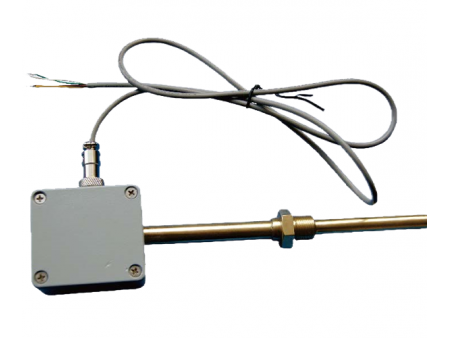

Differential Pressure Transmitter

The differential pressure transmitter is designed to measure the pressure difference between its two ends. It outputs standard signals such as 4~20mA, 0~5V. Unlike common pressure transducers, the differential pressure transmitter is available with two pressure interfaces. Typically, it consists of the positive end and negative end, and the positive end pressure should be higher than negative end.

In order to prevent mediums in pipelines entering into the transmitter, the pressure sensing diaphragm and the transmitter is connected by capillary tubes filled with fluids. Differential pressure transmitters are used for measuring the level, flow and pressure of liquids, gases and steam, and then convert these parameters into 4-20mA DC signals. They also support mutual communication via BRAIN or HART 275/375 handheld communicators which can also be used to set and monitor pressure transmitters.

Applications

1. High viscosity mediums under high temperature conditions

2. Mediums easy to crystallize

3. Precipitable mediums with solid particles or suspended particles

4. Mediums with strong corrosion or high toxicity

Differential pressure transmitter can avoid environmental pollution caused by leakage of connecting pipe. It also eliminates the demand for frequent filling of spacer fluid.

5. Continuous precision measurement of interface level and density

The remote seal transmitter avoids the mixture of mediums under different periods of time, which makes sure the measurement results can authentically reflect the process variation

6. For places with high requirement on sanitary level

Differential pressure sensor is often found in production factories for foods, beverage and medicine. Parts of our differential pressure transmitters that contact with mediums are manufactured conforming to sanitary standards, and are easy for cleaning to prevent cross contamination.