Flow Control Push-In Fittings

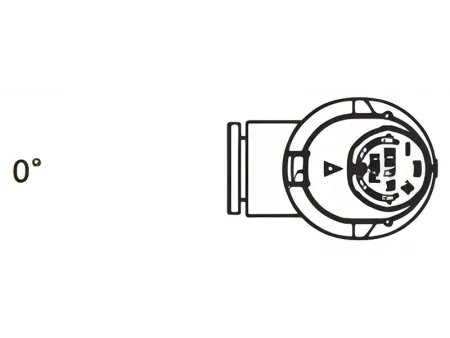

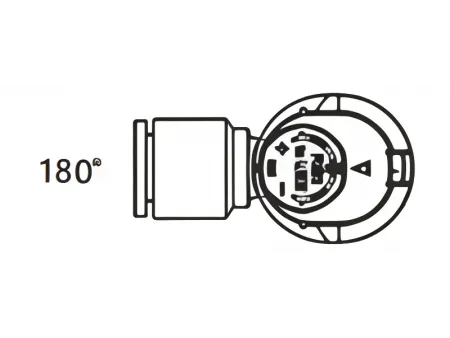

Flow control push-in fittings, also known as elbow fittings, adopt a special scale ring design that allow fine flow adjustment down to 0.1 L/min, with a repeat positioning accuracy of ±2%. This eliminates the manual trial-and-error estimation of conventional flow control valves, enabling precise flow control. Full customization is available from materials, port types, performance parameters, functional extensions, appearance, markings, etc., to meet your specific system requirements.

We recommended quick push-in fittings with nickel-plated brass bodies and NBR seals. These fittings support one-handed operation, with over 100,000 cycles, and provide cost-effective durability for high-frequency compressed air systems.

It is recommended to choose IP67-rated oil-resistant fittings made of stainless steel bodies and FKM seals, with threaded locking designs for secure sealing under vibration.

Select anti-static fittings with PPS conductive materials and IP65-rated sealing. It has a surface resistance of <10⁶ Ω, which prevents dust adsorption, ideal for chip (semiconductor) packaging and PCB assembly equipment.