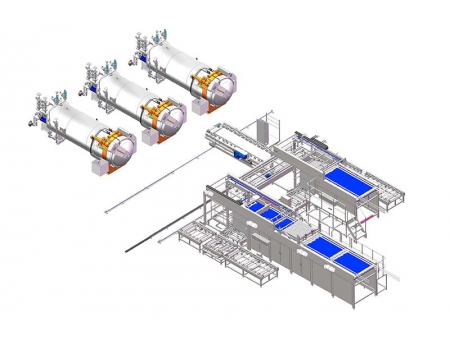

Automatic Retort Loading & Unloading System

Batch retort loading unloading process for cans and bottles

This automatic loading and unloading system is mainly used in cans or bottles packaging lines to accomplish a completely automatic loading and unloading process, involving loading of canned products in retort cages prior to sterilization, conveying into and out of the retort chamber and retort cage unloading after sterilization. When equipped with two conveyors at both ends, the automatic retort loading and unloading system can be positioned between canning equipment and can cleaning & packaging equipment to achieve unmanned production in the sterilization workshop. The entire system features a intelligent control system to complete automatic loading and unloading process without human interference.

Whether you are a packaging company looking for autmatic retort loading and unloading system or a canned food factory need a complete packaging line, you can rely on SUMPOT retort canning line to handle large quantities of canned or bottled food products.

This automatic retort loading and unloading system is mainly used in sterilizing applications for food products packaged in metal cans, glass jars and PE bottles.

- Ideally alternative to manual tedious tasks of retort cage loading and unloading, greatly saving labor intensity;

- Fully automated loading and unloading operations are implemented by computer control, without requiring human operator intervention;

- Production quality and efficiency will not be affected by operator's emotion, ensuring the safety and quality standardization;

- 24-hour continuous operation, yielding a higher profit for manufacturers;

- Less labor cost, reduced production management cost;