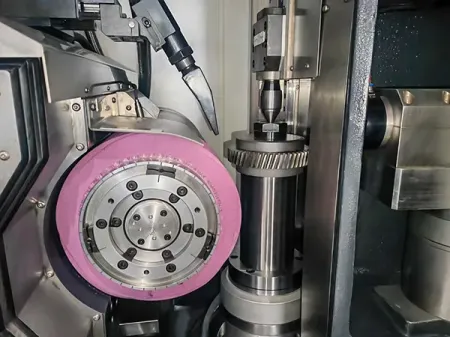

CNC Gear Grinding Machine

The YK7226 CNC grinding machines are designed for precise gear grinding in sectors such as instrumentation, automotive components and high-precision planetary reducers. It handles module 0.5–4 mm and workpieces up to Ø260 mm, covering the typical range required for small and medium gears. Grinding accuracy reaches GB3, which allows the machine to handle detailed finishing requirements as well as stable, efficient batch production.

- Max. working diameter (mm): ∅100

- Working module (mm): 0.5–2

- X-axis travel (mm): 270 (100-370)

- Y-axis travel (mm): 190 (0-190)

- Z-axis travel (mm): 300 (150-450)

- Z1-axis travel (mm): 350 (475–825)

YK7210 gear grinding machines use a continuous generative grinding method that works in a motion pattern similar to hobbing. It is suitable for module 0.5–2 mm and workpieces up to Ø100 mm, making it a good choice for small gears that require both accuracy and consistent production efficiency.

- Max. working diameter (mm): ∅260

- Working module (mm): 0.5–4

- X-axis travel (mm): 245 (112.5-372.5)

- Y-axis travel (mm): 220 (0-220)

- Z-axis travel (mm): 280 (170-450)

- Z1-axis travel (mm): 315 (335–650)

- The gear grinding machines use a continuous generative grinding method with a motion pattern similar to hobbing, allowing efficient and accurate grinding for large batch production. The main structure follows a high-rigidity, thermally balanced and modular design.

- They offer stable performance through high precision, strong rigidity and efficient cutting, supported by a complete software package and straightforward operation.

- Built in a vertical layout and composed of the main body, electrical cabinet, oil-mist extractor, hydraulic unit and cooling system. Equipped with the FANUC 31i-B CNC system with seven controlled axes and five synchronized axes, including X, Y, Z and X1 linear axes, plus A, B and C rotary axes and a dedicated wheel-dressing axis (B1).

- Suitable for gear-component production in automotive applications, gear reducers and intelligent-robot industries.

Gear components used in automotive systems, reducers, and smart-robot applications

| Model | | | |

| Max. working diameter (mm) | ∅100 | ∅260 | |

| Working module (mm) | 0.5–2 | 0.5–4 | |

| X-axis travel (mm) | 270 (100-370) | 245 (112.5-372.5) | |

| Y-axis travel (mm) | 190 (0-190) | 220 (0-220) | |

| Z-axis travel (mm) | 300 (150-450) | 280 (170-450) | |

| Z1-axis travel (mm) | 350 (475–825) | 315 (335–650) | |

| Grinding head swing angle (°) | ±45 | ±45 | |

| Max. grinding wheel size (OD×ID×W) (mm) | ∅275×∅160×125 | ∅275×∅160×125 | |

| Rapid traverse speed (X/Y/Z) (m/min) | 10 | 10 | |

| Workpiece Spindle | Rated power (kW) | 15 | 15 |

| Rated torque (N.m) | 119 | 80 | |

| Max. Workpiece Diameter spindle speed (r/min) | 2000 | 2000 | |

| Grinding Spindle | Rated power (kW) | 25 | 25 |

| Rated torque (N.m) | 119 | 119 | |

| Max. grinding spindle speed (r/min) | 7000 | 7000 | |

| X1/X2-axis servo motor | Rated power (kW) | 4 | 4/0.5 |

| Rated torque (N.m) | 22 | 22/2 | |

| X/Y/Z/A-axis servo motor | Rated power (kW) | 4/2.3/4/2.3 | 4/2.3/4/2.3 |

| Rated torque (N.m) | 22/8/22/8 | 22/8/22/8 | |

| W1/W2-axis servo motor | Rated power (kW) | / | 1 |

| Rated torque (N.m) | / | 4 | |

| C3/C4-axis servo motor | Rated power (kW) | / | 2.3/1 |

| Rated torque (N.m) | / | 8/4 | |

| Dresser diameter (mm) | ∅110 | ∅110 | |

| Max. dresser speed | 1500–6000 | 1500–6000 | |

| Machine dimensions (L×W×H) (mm) | 3700×4120×3180 | 3700×4120×3180 | |

| Total power (kVA) | 70 | 70 | |

| Machine weight (kg) | 12000 | 15000 | |