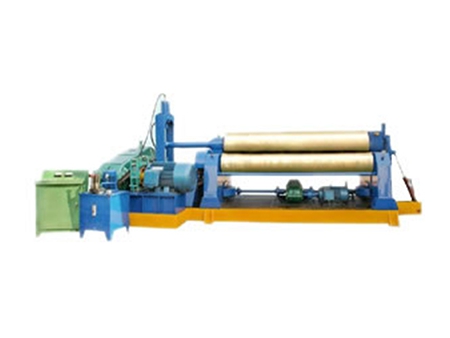

Cold Rolling Mill

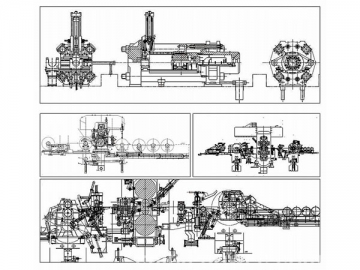

We also develop and produce various rolling mills, including two, four and six roller cold rolling mills, four roller reversible cold rolling mills, two roller temper rolling mills, three or four connected mills, two and three roller hot rolling mills, and a complete line of auxiliary machines.

| Model | ||||||||||

| Working Roll Diameter (mm) | φ120 | φ150 | φ165 | φ175 | φ200 | φ250 | φ320 | φ350 | φ400 | φ500 |

| Roller Length (mm) | 160 | 220 | 250 | 250-400 | 250-400 | 300-500 | 400-600 | 400-600 | 800 | 1000 |

| Rolling Pressure (T) | 65 | 100 | 100 | 100 | 100 | 120 | 150 | 150 | 160 | 260 |

| Raw Strip Thickness (mm) | ≤2.5 | ≤3 | ≤4 | ≤4 | ≤4 | ≤6 | ≤10 | ≤10 | ≤20 | ≤30 |

| Finished Strip Thickness (mm) | 0.15 | ≥0.35 | ≥0.35 | ≥0.35 | ≥0.35 | ≥0.40 | ≥0.40 | ≥0.40 | ≥0.50 | ≥0.60 |

| Strip Width (mm) | 10-100 | ≤150 | 180 | 300 | 300 | 370 | 450 | 450 | ≤600 | ≤800 |

| Rolling Speed (m/min) | 15 | 15 | 18 | 18 | 20 | 20 | 20 | 20 | 20 | 20 |

| Main Motor Power (kw) | 22 | 37 | 45 | 45 | 55 | 75 | 90 | 90 | 155 | 160 |

| Screwdown Gear Power (kw) | 1.5 | 2.2 | 2.2 | 2.2 | 3 | 3 | 5.5 | 5.5 | 5.5 | 7.5 |

| Screwdown Gear Speed (ms/s) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.12 | 0.12 |

| Reducer Model | JZQ500 | JZQ750 | JZQ750 | JZQ750 | JZQ850 | JZQ850 | JZQ1000 | JZQ1000 | ZL115 | ZL130 |

Applications

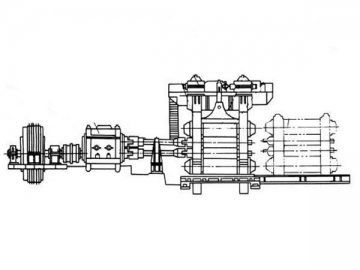

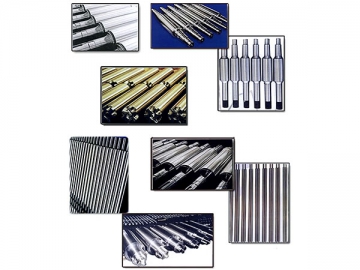

Our four roller cold rolling mill is suitable for intermediate rolling and precision rolling of plain carbon steel, alloy steel, copper-aluminum and stainless steel strips. The thickness of our finished products from the precision rolling process is equal or greater than 0.10mm. The rack, screwdown gear and roll system are all significantly improved based on the original prototype, which contributes to a large rolling force, high precision and great stability and makes the mill suitable for finish rolling of high quality steel and stainless steel.

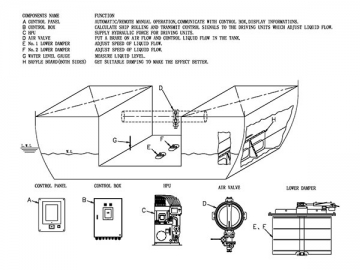

Components

Our four roller cold rolling mill can be driven by working roll or supporting roll. It includes the main motor, reducer, herringbone gear stand, universal spindle and rack. In addition, a one-piece pedestal is used, which facilities installation and debugging.

| Model | ||||||

| Working Roll Diameter (mm) | φ45 | φ70 | φ90 | φ135 | φ165 | φ170 |

| Roller Length (mm) | 250 | 250 | 250-300 | 250-350 | 350-400 | 400 |

| Rolling Pressure (T) | 65 | 80 | 100 | 120 | 240 | 280 |

| Raw Strip Thickness (mm) | 1 | 1.2 | ≤1.5 | ≤2.7 | ≤4 | 4 |

| Finished Strip Thickness (mm) | 0.05 | 0.08 | ≥0.10 | ≥0.18 | ≥0.25 | 0.3 |

| Strip Width (mm) | 20-200 | 30-200 | 230 | 250 | ≤300 | 300 |

| Rolling Speed (m/min) | 18 | 18 | 25 | 25 | 25 | 25 |

| Main Motor Power (kw) | 22 | 30 | 45 | 75 | 90 | 90 |

| Screwdown Gear Power (kw) | 2.2 | 2.2 | 3 | 4 | 5.5 | 7.5 |

| Screwdown Gear Speed (ms/s) | 0.06 | 0.06 | 0.06 | 0.08 | 0.08 | 0.08 |

| Reducer Model | JZQ650 | JZQ650 | JZQ750 | JZQ850 | JZQ1000 | JZQ1000 |

Applications

Our six roller rolling mill is suitable for rolling of wide strips, finishing strips and thin strips. It is widely used to roll plain steel and stainless steel. Equipped with a drawing device on the intermediate roll, the mill eliminates the need for arc grinding, thus effectively and precisely controlling the shape of steel plate. The bending roller used features a high rolling capacity and it is able to greatly reduce cracking on the edges of the rolls.

Components

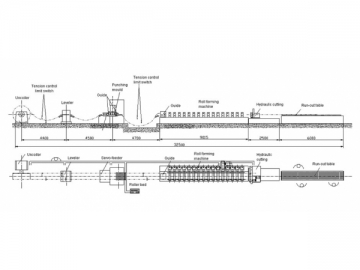

Our six roller cold rolling mill includes the uncoiler, five roller leveler, main motor, hydraulic winding machine, desktop trolley, belt press and electric control system.

| Model | Rolling Width (mm) | Rolling Speed (m/s) | Rolling Force (KN) | Feed Size of Steel Strip | Inner/Outer Diameter of Steel Coil |

| 400(450) | 0.4-4.0 | 3000 | 3.0×350 | φ410/φ1300 | |

| 700(800) | 0.4-5.0 | 6500 | 4.0×600 | φ508/φ1500 | |

| 900(1000) | 0.5-8.0 | 10000 | 4.0×800 | φ508/φ1700 |