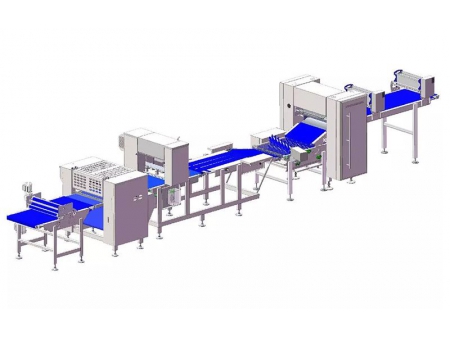

Croissant Make-Up Line

Request a Quote

Croissant make-up line integrates automatic cutting, shaping, and curling to enable industrial-scale croissant manufacturing. Laminated dough is simply fed into the line and processed into custom-shaped croissants with precision and consistency.

Thanks to its compact unit design, this croissant production line allows food manufacturers to produce croissants efficiently, using less space and a smaller investment.

Laminated dough should be prepared in advance before being conveyed to the processing table. To streamline this step, manufacturers can utilize our compact and flexible dough sheeters.

Parameters

| Line model | ZKS650 |

| Line type | Straight line |

| Belt width | 650 mm, 850 mm, 1050 mm, and other sizes |

| Dough width | 600 mm, 800 mm, 1000 mm |

| Dough thickness | 3mm-8mm (adjustable) |

| Industrial output | 3000-11000 pcs/hr |

| Product size | 20g, 25g, 60g, 80g, 120g, |

| Fillings | With or without |

| Power | 15 kW |

| Voltage | 380 V, 50 HZ, 3 PH (can be supplied based on production area) |

Features

- Supports various sizes and shapes on a single line.

- Abnormal data can be detected and optimized via a remote control system.

- Dough thickness is automatically adjustable.

- Built with food-grade 304 stainless steel and PU belts for enhanced durability.

- Requires minimal investment and floor space.

- Compared to manual production or small-scale machines, this line delivers high-quality croissants with greater automation and efficiency.

Components of Croissant Make-Up Line

- Traingular shaped cutting tools

Cutting molds can be customized based on croissant dough sizes. - Rotation unit

Changes the dough direction for easy forming. - Forming unit

Curls the triangle dough into croissants tightly.