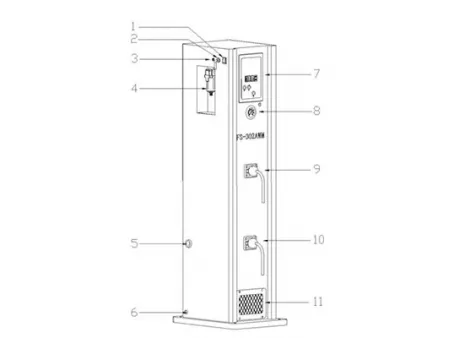

Medical High Purity Nitrogen Generator

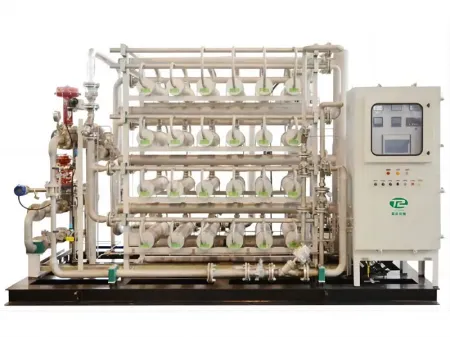

Medical high purity nitrogen generator is a common machine used in food and pharmaceutical industries. It can be extensively in nitrogen protection for synthetic drugs, pure nitrogen isolation in biotech engineering, nitrogen sealing for production of preparation, such as large infusion, water injection, powder injection and lyophilized agent, etc. This machine is composed of three parts, compressed air post-treatment system, PSA pressure swing adsorption system and precision gas filter sterilization system. Advanced international PSA production process is adopted so nitrogen purity is at least 99.999% which is in line with GMP production requirements of international pharmaceutical industry.

Detailed Specifications| Model | DYF-1 | DYF-5 | DYF-10 | DYF-20 |

| Productivity | 1m3/h | 5m3/h | 10m3/h | 20m3/h |

| Purity | >99.999% | >99.999% | >99.999% | >99.999% |

| Outlet Pressure | 0.25-0.6Mpa | 0.25-0.6Mpa | 0.25-0.6Mpa | 0.25-0.6Mpa |

| Compressive air | 0.4m3/min | 0.81m3/min | 1.5m3/min | 3m3/min |

| Power (exclude air compressor) | 220V/50HZ 1KW | 220V/50HZ 1KW | 220V/50HZ 1KW | 220V/50HZ 1KW |

| Dimension | 853*705*1500mm | 1180*980*1950mm | 1500*1200*2200mm | 1800*1400*2500mm |

| Weight | 260Kg | 700Kg | 1000Kg | 1500Kg |

Medical high purity nitrogen generator has excellent performance. In the first place, low-carbon austenitic stainless steel container pipeline and closed casing are used in machine, high polishing treatment and unique structural adsorber are adopted to ensure production of high purity nitrogen. Secondly, front and rear double precision filters as well as adsorption cylinder wall designed and manufactured according to GMP requirements are used to ensure clean, sterile and non-pyrogenic nitrogen. International brand molecular sieve can ensure long service life. Normally, service life of molecular sieve is 8-10 years. At the same time, to ensure long-time and continuous production, international brand piping pneumatic valve and solenoid valve are used to guarantee service life more than 1.5 million times.

Mitsubishi PLC program controller and KY-2N analyzer are adopted in medical high purity nitrogen generator so PLC automatic control and monitoring can be implemented. Of course, man-machine interface operating system, transmitter converting digital design, real-time dynamic display of the technical parameters and automatically switching monitoring are also available for customers to choose. In order to increase nitrogen production, increasing amount of compressed air and appropriate adjustment of the pressure and flow can be used.

We are a China-based semi automatic capsule filling machine manufacturer and supplier. Our products include medical hard capsule filling machine, medical high purity nitrogen generator, PTP aluminum foil blister packing machine and capsule sorting polisher, etc.