oxygen generators

Our PSA oxygen generator can separate oxygen from compressed air utilizing zeolite molecular sieve (ZMS) under pressurization. For PSA oxygen generator, the compressed air is first purified to remove the moisture, oil and dust. Then the purified air will pass through adsorption tower filled with ZMS. As nitrogen has a higher diffusion rate in ZMS pores, the sieve will adsorb the nitrogen and moisture over oxygen, allowing the oxygen to pass as product gas at pressure. After de-pressurizing, the sieve releases adsorbed gases into the atmosphere, and the process can then be repeated.

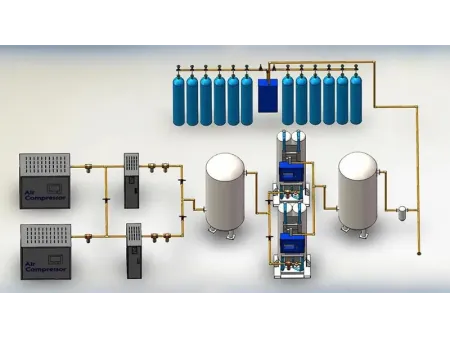

Two adsorption tower will be installed in parallel in PSA oxygen generator, one tower begins the adsorption phase while other tower regenerates by de-pressurizing. The PLC controller manages process valves with built-in logic for an automatic stop/start for continuous oxygen production. The whole system is composed of purification system for compressed air, air condenser, adsorption tower and oxygen buffer tank. PSA oxygen generation technology is widely used in industrial and medical applications for its efficiency, cost-effectiveness and low maintenance requirements.

- Oxygen capacity: 5-200Nm³/h

- Oxygen purity: 90%-94%

- Oxygen pressure: 0-0.5Mpa

- Oxygen dew point: -40℃ (atmospheric pressure)

- The compressed air will be purified first through the purification system, as clean and dry air can help prolong the service life of the molecular sieves

- Pneumatic valves support quick opening and closing without leakage, which makes this PSA oxygen generator satisfy the frequent usage of pressure swing adsorption (PSA) technology with long service life and high reliability

- Adopt the usage of latest molecular sieve, and complete process design for integrated and efficient production

- Adopt continuous systematic improvement and always equipped with latest production technology to save energy and lower the production cost

- Adopt compact design to reduce the space used for installation

- Use PLC control to ensure stable performance and automatic operation with low annual operation error rate