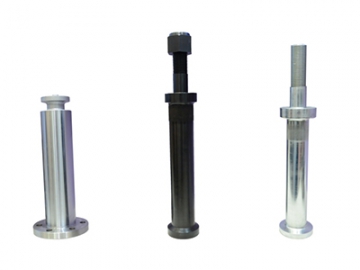

Piston Rod

In order to be wear-resistance and anti-corrosion, our piston rods undergo several complicated processes, such as grinding, chrome plating and mirror polishing. Such advantages make our stainless steel piston rod widely used in these following places: air cylinders, oil cylinders, packaging, woodworking, textile equipment, printing and dyeing machinery, die casting machine, injection molding machine and other machinery guide rod.

Parameters of Chrome Plated Piston Rod

Material: High quality 45# steel

Tolerance of external diameter: f7-f8

Roughness: Ra0.2-0.4

Thickness of chrome plate: 0.015-0.025mm

Hardness: HV700-1150

Straightness: 0.05-0.10m/m

Standard length: 1-6m

We also provide high-frequency processed products, with a length of 1-3mm and hardness of HRC45℃~52℃

Notes: You can choose different types according to your actual demand.

Thickness of Chrome Plate

Under air pressure: 0.02mm

Under oil pressure: more than or equals to 0.02mm

Stainless Steel Piston Rod

Equipped with advanced techniques of cold drawing, fine grinding and high-precision polishing, our chrome rods have good capacity of wear-resistance and anti-corrosion. These chrome plated steel rods also meet national standards and find huge application in oil cylinder, air cylinder and damper.

How to Test the Hardness

The hardness measurements usually include damaging and non-damaging measurement. However, non-damaging measurement only means a very little damage rather than no damage. The most representative device is ultrasonic hardness tester. Just like the Vickers hardness tester, it also leaves a little indentation (about 0.5-2mm) on the workpiece while measuring.

Manufacture Process

1. This is a warehouse of raw materials. Materials include 45#, 40cr, 20crMnTi carbon steel. Clients can also choose other materials according to your actual condition.

2. Stripping process: Our automatic centerless machine is stripping raw materials. It makes the post fine-processing much easier.

3. Straightening and calendering machine is mainly used for the precision straightening and calendering of medal rods in accordance with the design drawing.

4. Fine polishing workshop

(1) The total fine polishing staff consists of over 30 highly trained technicians, each of them possessing over 10 years of industrial experience. We also have 7 CNC centerless grinding machines for the cylindrical processing of steel materials, achieving a maximum diameter of Φ8mm-Φ1000mm and a length of 13,000 mm. thanks to our committed technicians and efficient machine, we can meet any processing requirements of clients.

(2) Cylindrical grinder: Our company totally has 4 cylindrical grinders. Among them, one is CNC cylindrical grinder, with a high degree of processing accuracy: cylindrical run-out < 0.02mm, straightness < 0.05mm, external diameter < 0.01mm. This grinder can satisfy any requirement for fine processing.

The whole processing is in strict accordance with the design drawing.

5. This is a picture of our electroplating workshop. Our technicians cover products with a chrome plate of 20 μm thick, vastly improving capacities like hardness, wear-resistance, temperature resistance and anti-corrosion.

6. Polishing machine: After those above steps, each workpiece will go through the polishing process. It makes products bright and beautiful, obtaining a roughness less than Ra0.3um.

7. Inspection: We have strict standards and requirements for products. When it comes to inspection, each component or part will be checked according to the design drawing. Besides, we adopt thickness measuring device for thickness inspection and pick out substandard products.

Pictures of inspection equipment

- MITUTOYO measuring device

- Roughness measuring device

- German’s chrome thickness measuring device

8. Packaging: We adopt film for product packaging, allowing for bumping and scratching during transportation.

9. Finished products