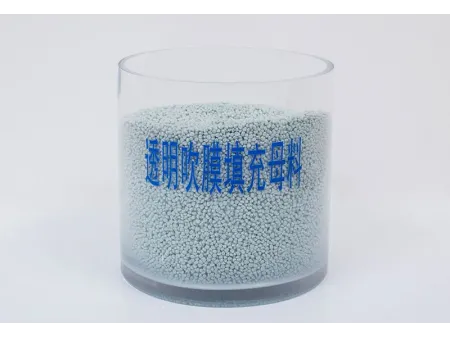

PE Filler Masterbatch for Transparent Blown Film, JH-205A(B)

Optimizing production without compromising quality is key for manufacturers of transparent blown films. Our PE filler masterbatch is formulated for use in transparent blown film applications. Using PE carrier resin and ultra-fine, high-transparency talc powder as the filler, the product undergoes surface activation treatment and is blended with dispersing agents and other specialized additives. The result is a masterbatch that provides excellent fineness, high transparency, and easy dispersion. It is non-toxic, odorless, and has a high filler content, offering superior flowability. The tensile strength, tear resistance, and elongation at break of the film remain consistent with national standards, while heat sealing performance is maintained. Adding the masterbatch in suitable quantities (up to 50%) does not affect transparency and significantly reduces production costs.

- Appearance: white granules

- Granule Size: ∅3×4mm

- Melting flow index: 1-6g/min (customizable)

- Whiteness: ≥85%

- Density: 1.7-1.8g/cm³

- Moisture & Volatile Matter: ≤0.3%

- Dispersibility: excellent, without crystal point

- Maintains critical strength and flexibility, ensuring the durability of transparent films without compromising quality

- Reduces the need for expensive PE resin by up to 50%, helping manufacturers cut production costs while maintaining product performance

- Lowers reliance on petroleum-based resins, contributing to more sustainable manufacturing practices

- Enhances flow properties, making the production process smoother and more efficient

- Increases the film’s smoothness and transparency, improving its suitability for printing and post-processing applications

- Offers improved thermal stability, making the film suitable for applications that require resistance to varying temperatures

Ideal for producing HDPE, LLDPE, LDPE, and BOPP films, this masterbatch is widely used in packaging films, grocery bags, greenhouse films, geomembranes, and more. It can also be applied in plastic extrusion, injection molding, and other processes.

- 25kg bags with PE waterproof lining

- Jumbo bags