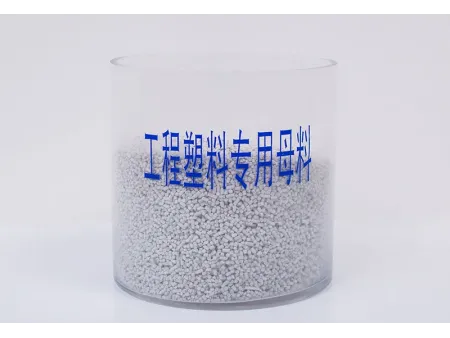

PP Filler Masterbatch

PP filler masterbatch is produced using PP as the carrier resin, combined with dispersing agents and special additives, followed by surface activation and extrusion. This masterbatch enhances the rigidity and heat resistance of PP products, improving surface smoothness and gloss. It is resistant to acids, alkalis, and high temperatures, and offers non-toxic, odorless, high-strength, and easy-to-disperse characteristics. As a key raw material in engineering plastics, sheets, pallets, automotive parts, bumpers, and various heat-resistant home appliance casings, it plays a significant role in reducing production costs while maintaining product quality. The recommended addition rate of 10-30% ensures enhanced performance in injection-molded products.

- Appearance: white granules

- Granule Size: ∅3×4mm

- Melting flow index: 2-5g/min (230℃, 15kg)

- Whiteness: ≥85%

- Density: 1.7-1.9g/cm³

- Moisture & Volatile Matter: ≤0.3%

- Significantly enhances the strength and heat resistance of plastic components for automotive and home appliances

- Improves both the appearance and mechanical properties of products

- Exhibits excellent stability and non-migration properties, ensuring long-lasting performance

PP filler masterbatch is widely used in automotive dashboards, interior trim, door panels, flooring, control boxes, seats, outer bumpers, and in the casings of home appliances like refrigerators, washing machines, and air conditioners.

- 25kg bags with PE waterproof lining

- Jumbo bags