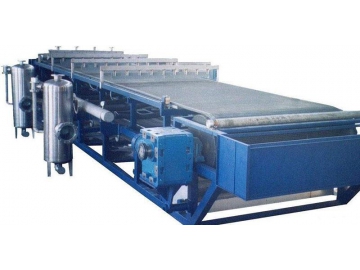

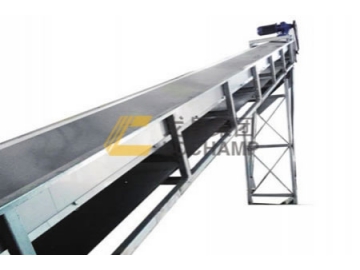

Belt Conveyor System

Request a Quote

Application

Belt conveyor systems are designed to transport loose or block materials, and they are widely used in mining, foundry, metallurgy, chemical, electricity and other industrial applications. According to the needs of different working lines, Vostosun can provide single, or multiple belt conveyors with other conveyors consisting of horizontal or tilted conveyor systems. The belt conveyor system can work for materials whose temperature is less than 50 ℃ when ambient temperature is in the range of -20~40℃ .

Applicable materials

Limestone, granite, marble, basalt, iron ore, pebble, quartz stone, shale, diabase, gold ore, copper ore, bluestone, coal, cobble, construction waste and etc.

| Belt width (mm) | Conveying length (m)/power (kW) | Conveying speed (m/s) | Conveying capacity (t/h) | ||

| 400 | ≤12/1.5 | 12-20/2.2 | 20-25/3 | 0.8-2 | 40-80 |

| 500 | ≤12/3 | 12-20/4 | 20-30/5.5 | 0.8-2 | 78-191 |

| 650 | ≤12/4 | 12-20/5.5 | 20-30/7.5 | 0.8-2 | 131-323 |

| 800 | ≤10/4 | 10-15/5.5 | 15-25/7.5 | 1.0-2 | 278-546 |

| 1000 | ≤10/5.5 | 10-20/7.5 | 20-25/11 | 1.0-2 | 435-853 |

| 1200 | ≤10/7.5 | 12-20/11 | 20-25/15 | 1.0-2 | 655-1284 |

| Remarks: Actual power depends on equipment matching | |||||

| Material | β | Material | β | Material | β | Material | β |

| Lump coal | 18° | 0-120 mm ore | 18° | Wet concentrate (moisture 12%) | 20° | Salt | 20° |

| Raw coal | 20° | 0-60 mm ore | 20° | Dry concentrate | 18° | Molding sand | 24° |

| Coal powder, washed product① | 21° | 40-80 mm kerogen shale | 18° | Screened limestone | 12° | Waste sand | 20° |

| Screened coke | 17° | 20-40 mm kerogen shale | 20° | Dry sand | 15° | Unscreened stone | 18° |

| 0-25 mm coke | 18° | 0-200 mm kerogen shale | 22° | Sand with gravel | 18-20° | Cement | 20° |

| 0-3 mm coke | 20° | Dry loose soil | 20° | Sand of quarry | 20° | Block dry clay | 15-18° |

| 0-350 mm ore ② | 16° | Wet soil | 20-23° | Wet sand | 23° | Powder dry clay | 22° |

| Remarks: ①including cleaned coal, medium coal and tailings. ②including ferrous metals, nonferrous metals, rocks, limestone and others. | |||||||

- Equipped with high performance driving roller.

- High performance roller: control the transverse position of the conveyor system effectively, avoiding the deviation of materials, and reducing the impact of materials on the belt.

- Tightener: achieve the necessary tension of belt to avoid the slide on the driving roller, make sure the deflection of the conveyor belt between the rollers is in the specified range.

- Conveyor belt with large conveying capacity: equipped with high quality conveyor belt, suited for large conveying capacities and large inclination angles, preventing skidding and aging effectively.

Related

mining materials handling, industrial conveyor, conveyor system

mining materials handling, industrial conveyor, conveyor system

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos