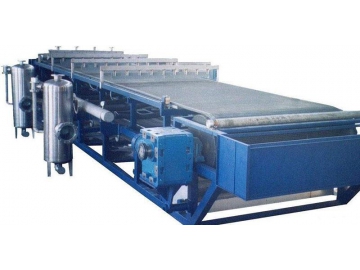

Vacuum Belt Filter

Application

Vacuum belt filter, equipment for solid-liquid separation driven by vacuum negative pressure, adopts rubber conveyor belt and it can accomplish the recycled industries continuously such as filtration, washing, drying, filter cloth and so on. The filter is applied to solid-liquid separation in metallurgy, mine, chemical engineering, paper-making, food, coal chemical industry, pharmacy, environmental industry and so on. Especially, it has good application in gypsum dehydration of flue-gas desulfurization(FGD).

Applicable materials

Potassium feldspar, coal, pyrites burning, coal ash, coal potassium fertilizer, sanitizer, granite, gold ore tailing, lead-zinc ore tailing, FGD gypsum, iron ore concentration, Feldspar, industrial waste water, steel slag desulphurization, sodium feldspar, activated carbon, potassium chloride, mortar, ardealite, drug sediments, copper ore concentrate, magnetite ore tailing, zeolites.

| Filtration width/m | 1.3 | 1.8 | 2 | 2.5 | 3.2 | 4 | 4.5 | ||||||||

| Filtration length/m | N(integer) | Filtration area/m2 | Weight /T | Filtration area/m2 | Weight /T | Filtration area/m2 | Weight /T | Filtration area/m2 | Weight /T | Filtration area/m2 | Weight /T | Filtration area/m2 | Weight /T | Filtration area/m2 | |

| 8 | 3 | 10.4 | 7.9 | 14.4 | 10.4 | 16 | 11.7 | 20 | 14.6 | ||||||

| 10 | 4 | 13 | 8.9 | 18 | 11.9 | 20 | 13.4 | 25 | 16.8 | 32 | 27.6 | ||||

| 12 | 5 | 15.6 | 9.9 | 21.6 | 13.4 | 24 | 15.1 | 30 | 19 | 38.4 | 30 | 40 | 42.4 | 54 | |

| 14 | 6 | 18.2 | 10.9 | 25.2 | 14.9 | 28 | 16.8 | 35 | 21.2 | 45 | 32.4 | 56 | 45 | 63 | |

| 16 | 7 | 20.8 | 11.9 | 28.8 | 16.4 | 32 | 18.5 | 40 | 23.4 | 51.2 | 34.8 | 64 | 47.6 | 72 | |

| 18 | 8 | 23.4 | 12,9 | 32.4 | 17.9 | 36 | 20.2 | 45 | 25.6 | 58 | 37.2 | 72 | 50.2 | 81 | |

| 20 | 9 | 26 | 13.9 | 36 | 19.4 | 40 | 21.9 | 50 | 27.8 | 64 | 39.6 | 80 | 52.8 | 90 | |

| 22 | 10 | 39.6 | 20.9 | 44 | 23.6 | 55 | 31 | 70.4 | 42 | 88 | 56.4 | 99 | |||

| 24 | 11 | 48 | 25.3 | 60 | 33.2 | 77 | 44.4 | 96 | 59 | 108 | |||||

| 26 | 12 | 65 | 35.4 | 83.2 | 46.8 | 104 | 61.6 | 117 | |||||||

| 28 | 13 | 89.6 | 49.2 | 112 | 64.2 | 126 | |||||||||

| 30 | 14 | 96 | 51.6 | 120 | 66.8 | 135 | |||||||||

| A(m) | N<5 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | |||||||||

| N≥5 | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.4 | ||||||||

| B(m) | N<5 | 0.45 | 0.45 | 0.45 | 0.45 | 0.52 | |||||||||

| N≥5 | 0.45 | 0.45 | 0.45 | 0.52 | 0.645 | 0.645 | 0.645 | ||||||||

| C(m) | N<5 | 1.3 | 1.3 | 1.3 | 1.3 | 1.6 | |||||||||

| 5≤N≤9 | 1.3 | 1.3 | 1.3 | 1.6 | 1.675 | 1.675 | 1.675 | ||||||||

| N>9 | 1.3 | 1.3 | 1.6 | 1.975 | 1.975 | 1.975 | |||||||||

| D(m) | N<5 | 2 | 2 | 2 | 2 | ||||||||||

| 5≤N≤9 | 2 | 2 | 2 | 2 | 2.2 | 2.2 | 2.2 | ||||||||

| N>9 | 2 | 2 | 2 | 2.25 | 2.25 | 2.25 | |||||||||

| E(m) | N<5 | 1.85 | 1.85 | 2 | 2 | ||||||||||

| 5≤N≤9 | 2 | 2 | 2 | 2.11 | 2.21 | 2.21 | 2.21 | ||||||||

| N>9 | 2 | 2 | 2.11 | 2.41 | 2.41 | 2.41 | |||||||||

| F(m) | N<5 | 0.86 | 0.86 | 0.86 | 0.86 | ||||||||||

| N≥5 | 0.91 | 0.91 | 0.91 | 1.105 | 1.205 | 1.205 | 1.205 | ||||||||

| H(m) | N<5 | 2 | 2 | 2 | 2.18 | ||||||||||

| 5≤N≤9 | 2.18 | 2.18 | 2.18 | 2.38 | 3.1 | 3.1 | 3.1 | ||||||||

| N>9 | 2.18 | 2.18 | 2.18 | 2.6 | 3.6 | 3.6 | 3.6 | ||||||||

| W(m) | 1.9 | 2.45 | 2.7 | 3.25 | 4.8 | 4.8 | 5.3 | ||||||||

- The filtrated mother liquor and washing filtrates for each segmented filter cake can be collected separately and it can realize co-current washing and counter-current washing.

- The overall structure of the belt filter adopts modular design, which can realize flexible assembling and save maintenance costs, easy to transport and install.

- The control system applies DCS technology thus can realize field control and remote automatic control.