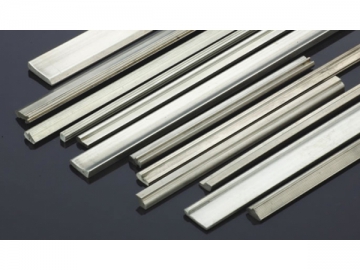

Deformed Copper-Nickel Alloys (Low-Nickel)

Categories: Bar & Wire Products-Special Alloy

Name: Deformed Low-Nickel Copper-Nickel Alloys

Number: BZn15-38, BZn12-38, BZn10-38

Features

High strength: Tensile strength ≥ 930Mpa, higher than that of common copper-nickel-zinc alloy (200MPa);

Ease of machining, deformation rate >80%, cold deformation rate>70%;

Bright color, high oxidation resistance;

Superior corrosion resistance;

Low cost: low density, 5% lower than the common copper-nickel-zinc alloy; low material cost reduces total cost by 10%;

| Articles | Specification |

| BZn15-38 | 0.6-12.0mm |

| BZn10-38 | 0.6-12.0mm |

| BZn8-38 | 0.6-2.0mm |

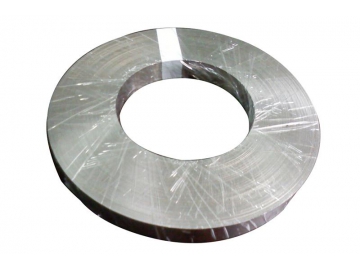

Advantages

1. Low-nickel copper-nickel alloy comes with a small density, light weight and attractive appearance.

2. It provides excellent resistance to corrosion and color deterioration. Specifically, the copper alloy will not discolor in a 24-hour man-made perspiration test, and retain its color remains unchanged after dipping in a detergent solution for 24 hours.

3. High abrasion resistance greatly extends its service life

4. The CuNi alloy has outstanding high and low temperature machinability. The maximum working modulus is up to 70%.

Applications

Our copper nickel alloys with low nickel content and outstanding deformation characteristics are ideal for the manufacturing of glasses, fittings, musical instruments, zippers, cupronickel jewelry, precision instruments, medical and sanitary engineering parts, elastic elements, utensils and daily necessities.

| Density (g/cm3) | Hardness (HB) | Tensile Strength (Mpa ) | Elongation (%) | Elastic Modulus |

| 8.26 | 95-210 | 420-1050 | ≥36% | 120-128Gpa |