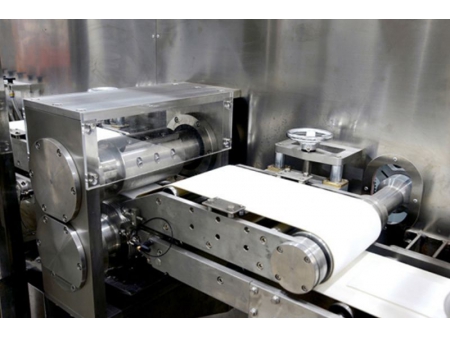

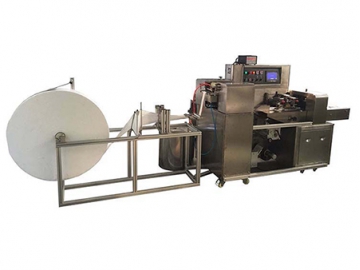

- Automatic Unwinding → In-Line Slitting → Web Guiding → Longitudinal Folding → Synchronous Conveying → Wetting and Cut-Off → Stacking and Counting → Wrapping Film Feeding → Packaging → Lid Application → Finished Product

Fully Fully Automatic Wet Wipes Folding Converting Machine

DCW-4300 Wet Wipes Line (30-120 pcs/pack)

Wet wipes machine integrating folding, wetting, stacking and packaging

Machine

- Production Speed 4800-6000 wipes per minute

- Cutting Speed 400-500 cuts per minute

- Fold Types Z-fold (interfold or non-interfold adjustable)

Product

- Open Wipe Length 160-220mm

- Folded Wipe Length 120-230mm

- Folded Wipe Width 90-110mm

This fully automatic wet wipe folding machine delivers impressive speeds of 400-500 cuts per minute with on-line slitting capabilities, ensuring precise handling of large fabric rolls while streamlining the production process to meet diverse manufacturing needs.

Equipped with reliable Mitsubishi electrical components, it is built for consistent performance and ease of operation. The innovative scissor-style cutter ensures clean, precise cuts while offering exceptional durability, even under high-speed production.

For manufacturers aiming to enhance efficiency and quality, this high-performance wet wipe folding and converting machine offers a dependable and effective solution.

This fully automatic wet wipe folding machine is designed to produce 30-120 pieces per pack of various types of wet wipes, including baby wipes, cosmetic wipes, feminine hygiene wipes, cleaning wipes, antibacterial wipes, kitchen wipes, pet wipes, and disinfectant wipes, making it versatile for personal care, household cleaning, and hygiene applications.

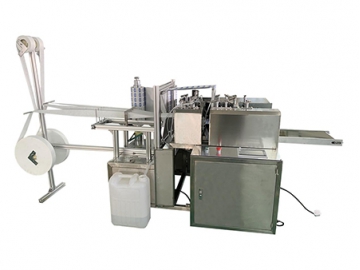

This fully automatic wet wipe production line integrates cutting, folding, wetting, stacking, packaging, and sealing into a single streamlined system. The lid applicator machine can be configured separately and requires only 1-2 operators for supervision.

- Automatic Unwinding

- Web Guiding

- Longitudinal Folding

- Wetting and Cut-Off

- Stacking and Counting

- Packaging

- Lid Application

- Finished Product Conveying

| Production speed | 4800-6000 wipes/min | Fold type | Z-fold |

| Cutting speed | 400-500 cuts/min (10-12 sheet per cut) Design speed: 560 cuts/min | Fold format | Interfold/non-interfold (adjustable) |

| Wipe material | Spunlace nonwoven fabric, wet-strength paper, thermal bond nonwoven fabric | Liquid adding tank | 600L×2 304 stainless steel tanks with agitator |

| Material weight | 35-80g/m² | Wetting range | 2.5-5 times, quantitative wetting (can be set by touch panel) |

| Number of parent rolls | Parent rolls on 2 shafts (automatic slitting of each parent roll into 5-6 narrower rolls, shaft diameter 76.2mm) | Cutting length | 120-230mm (double blade cutting) |

| Parent roll size | Width: 800-1320mm Diameter: < 1200mm | Stack count | 20-120 sheet, 10-12 sheet/stack |

| Voltage | AC380V 50HZ three-phase five-wire | Stack height | Max. 100mm |

| Total power | 15kW | Air pressure | 0.6-0.8MPa |

| Open wipe length | Length: 120-230mm (customizable) | Machine dimensions (L×W×H) | 9830×3300×1800mm |

| Open wipe width | 160-220mm (customizable) | Liquid tank size | 900×1900×1900mm |

| Folded wipe length | 120-230mm (customizable) | Machine weight | Approx. 5t |

| Folded wipe width | 90-110mm (customizable) |

- Semi-servo design, compact structure, easy operation and maintenance.

- CE / UL standard electrical parts, safety door and emergency stop.

- CNC machined mechanical parts.

- Auto temperate adjustment for electrical thermo parts.

- Inverter controlled motors, universal couplings adopted for main parts.

- No machine stop when adjusting phase.

- Main electrical components: Mitsubishi (Japan)

- Pneumatic components: AirTAC (Taiwan)

- Key bearings: NTN/NSK (Japan)

- Transmission system: Enclosed gearbox timing belt universal coupling

- Motor control: Each motor can be independently started and stopped via the touch screen interface.

- Emergency stop features: Two emergency stop buttons and one pull-wire stop system; pressing any emergency stop halts the machine immediately.

- Operating interface: LCD touch display with real-time production parameter settings, daily production data recording and storage, MES data interface, and remote assistance and monitoring capabilities.

- Control modes: Offers both automatic and manual modes to suit production control needs.

- Fault alerts: Automatic shutdown or alarm notifications in case of equipment malfunction.