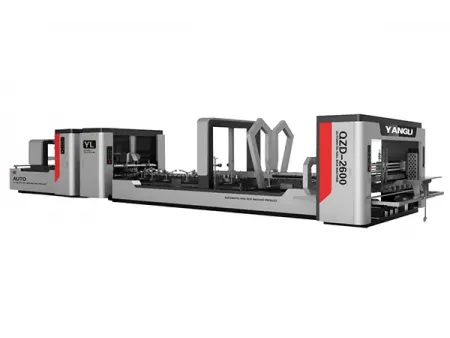

Fully Automatic Folder Gluer & Stitcher Machine, CZYL-FSM

Carton Box Folding, Gluing and Stitching Machines

The fully automatic folder gluer & stitcher machine is composed of four main sections: paper feeding, gluing and folding, stitching and pressing, and counting and stacking. It features digital speed regulation and microcomputer amplitude control, offering a simple, fast, reliable, and precise operating mode. With automatic feeding, gluing, folding, counting, and stacking, the machine achieves an average gluing speed of 220 boxes per minute, a maximum output of 5000 boxes per minute, and a stitching speed of 80 pieces per minute, combining high efficiency with energy saving and environmental protection.

- Integrated System

Includes feeding, folding, stitching, pressing, counting, and stacking for a complete end-to-end solution. - High Productivity

Average gluing speed of 220 boxes/min, maximum up to 5000 boxes/min, and stitching speed of 80 pieces/min. - User-Friendly Control

Digital speed adjustment, microcomputer amplitude modulation, Panasonic PLC system, and color touchscreen with upgrade-ready ports. - Consistent Quality

Effectively avoids scissor-mouth and fish-tail defects seen in traditional gluing and stitching, ensuring accuracy and firm bonding. - Eco-Efficient

Delivers stable performance with reduced energy consumption and reliable environmental compliance. - Built to Standards

Electrical components conform to European safety norms, ensuring durability and easy maintenance.

| Model | 2600 |

| Max. sheet length (mm) | 2600 |

| Min. sheet width (mm) | 820 |

| Machine weight (ton) | 6.3 |

| Motor power (kW) | 18 |

| Min. front mark of carton (mm) | 210 |

| Min. side mark of carton (mm) | 170 |

| Max. cardboard width (mm) | 1400 |

| Min. cardboard width (mm) | 300 |

| Total machine length (m) | 16 |

Feeder Section

- The secondary creasing system ensures more accurate folding positions, prevents carton breakage, and delivers clean, attractive crease lines.

- The secondary correction mechanism completely eliminates misalignment, improving the qualified product rate.

Gluing & Folding Section

- Linked with the feeder and controlled by variable frequency speed regulation, this section synchronizes folding with creasing.

- Equipped with imported multi-hole conveyor belts and continuous suction, it achieves automatic folding while preventing skewing, slipping, or jamming, particularly with heavy-duty, laminated, or coated cartons ensuring stable and efficient operation.

Stitching & Pressing Section

- The stitching head is built from special wear-resistant materials for durability. Driven directly by a servo motor, it ensures stable and precise operation.

- A dual-reel automatic wire feeding system with two 20 kg flat-wire reels reduces wire changes and enhances productivity.

- Supports multiple stitching modes including single, double, reinforced, and head-to-tail nails with speeds up to 600 stitches per minute.

Counting & Stacking Section

Completed cartons are automatically aligned, counted, stacked, and neatly delivered, ensuring accurate and reliable output.