Hydrocyclone

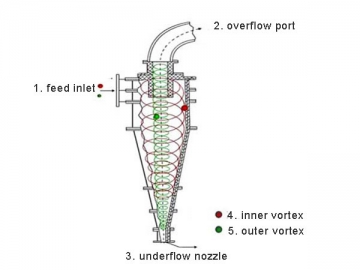

Normally, a hydrocyclone has a cylindrical section at the top where the material is being fed tangentially. In this way, the centrifugal force imposed on the material will be enhanced significantly and turbulence caused by sudden divergency of the material at the feed inlet will also be greatly alleviated. As a result, the classifying efficiency will be highly improved and the slurry will run steadily, thus creating less impact on the feed device. Moreover, if the length ratio between the cylindrical section and the conical section and the depth of the overflow pipe are reasonable enough, the classifying effect will be much better. Wear resistant rubber is adopted to make the lining, thereby extending the service life of the hydrocyclone by 2 to 4 times.

Our hydrocyclone features a unique structure. It utilizes a segmental cylinder, which makes it possible to increase or reduce the height of the cylinder as required. The overflow fineness will be enhanced with the increase of the height. The optimal fineness is about 10μm. In addition, each cylinder diameter is corresponding to one particular combination of cylinder and cone. Our hydrocyclone is able to ensure maximum tangential speed even at the minimum overall length. Therefore, the centrifugal force will be magnified, which further boosts classifying efficiency.

Our hydrocyclone has multiple working modes, which include classification, concentration, dehydration, desliming, degritting, washing, super-fine classification,etc.

Technical Parameters| Model | Diameter (mm) | Cone Angle (degree) | Overflow Fineness (μm) | Capacity (m3/h) | Overflow Pipe Diameter (mm) | Feed Inlet Area (mm2) | Apex Nozzle Diameter (mm) | Dimensions (Length*Width*Height) (mm) | Weight (kg) |

| 125 | 20 | 20-50 | 3.1-6.1 | 14,18,25,35 | 25×10 | 15,25 | 260×320×646 | 57 | |

| 150 | 20 | 35-75 | 7.5-15 | 20,40,32,25 | 22×22 | 32,24,16 | 570×426×1123 | 128 | |

| 250 | 20 | 40-100 | 10-39 | 26,34,50,69 | 50×20 | 20,25,35 | 852×516×1273 | 205 | |

| 300 | 20 | 45-105 | 37-43 | 65,75 | 47×60 | 35,40 | 852×525×1940 | 287 | |

| 350 | 20 | 50-110 | 74-90 | 115,105,95 | 80×65 | 80,70,60 | 955×680×2299 | 430 | |

| 500 | 20 | 60-120 | 170-220 | 180,160,140 | 110×120 | 110,90,70 | 1090×811×2835 | 718 |