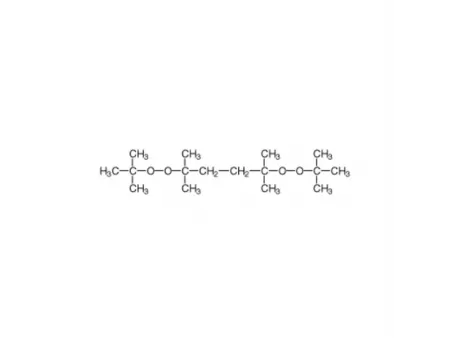

2,5-Bis(tert-butylperoxy)-2,5-dimethylhexane (BPDH)

- Chemical Family Organic Peroxide

- Molecular Formula C₁₆H₃₄O₄

- Molecular Weight 290.44

- UN No. 3105

- IMO/IMDG 5225 5.2

- Road Transport (ADR) 5.2 5b

- Rail Transport (RID) 5.2 5b

- Sea Transport (IMDG) 5.2-01

- (organic peroxide, Type C, liquid, packing group II)

Half-Life Period

- 0.1 hour 156℃

- 1 hour 134℃

- 10 hours 115℃

- Theoretical active oxygen content: 11.02%

- Available oxygen: 10.1% min

- Self-accelerating decomposition temperature (SADT): 80℃

- Hazardous temperature (Tem): 75℃

- Storage temperature (Ts min/Ts max): 10/40℃

- Activation energy E: 155.49, A=1.68E 16 (S⁻¹)

- Tert-butyl hydrogen peroxide content: 0.3% max

- Chromaticity: 50Pt-Co max

- Density: 870kg/m³ (20℃)

- Refractive index: 1.422

- Appearance: colorless clear liquid, can be diluted with the solvent specified by customer

- Solubility: Insoluble in water, soluble in most organic solvents

- Major decomposition products: tert-butyl alcohol, 2,5-dimethyl-2,5-hexanediol, isobutylene, methane, acetone

BPDH is a versatile organic peroxide cross-linking agent suitable for a wide range of polymers. It is FDA-approved for use in rubber products intended for repeated applications. We offer BPDH in three concentrations: 90%, 50%, and 30%, to accommodate various industrial needs.

- BPDH is highly effective as a cross-linking agent for polyethylene, including both LDPE and HDPE, as well as ethylene-vinyl acetate copolymers. Cross-linking occurs at temperatures above 170°C, while no cross-linking happens below 140°C. It is typically used at concentrations between 0.5% and 3% by weight, although for more resistant materials, the dosage can be increased up to 5%.

- In rubber production, it serves as a high-temperature vulcanizing agent, especially for vinyl silicone rubber. The vulcanized rubber exhibits strong tensile strength and high hardness, making it suitable for applications that require durable, high-performance materials.

- It is also an excellent degradation agent for polypropylene, performing well at temperatures between 200°C and 220°C. Used in small concentrations (0.01% to 0.1%), it helps create polypropylene with a high melt flow index and consistent molecular weight distribution, making it ideal for high-speed spinning, coatings, films, and casting plastics. Widely used in producing degradation masterbatches.

- Additionally, this compound acts as a high-temperature curing agent for unsaturated polyester, providing efficient curing in various industrial processes.

- Oral LD₅₀ (rats): Greater than 3200 mg/kg

- Dermal LD₅₀ (rabbits): Greater than 4.1 mg/kg

- Acute Intraperitoneal Toxicity LD₅₀ (mice): 1700 mg/kg

- Health Hazards: BPDH may irritate the eyes, skin, and mucous membranes, and can cause dermatitis.

- Routes of Exposure: Inhalation, ingestion, and skin absorption.

-

Packaging

Standard packaging is 25 kg, but custom packaging options are available upon request, with PE materials used for durability.

-

Validity

When stored and transported according to the manufacturer’s recommendations, the product maintains its quality for up to three months.

-

Safe Handling

Store BPDH in a cool, well-ventilated area, ensuring the storage temperature doesn’t exceed 30°C.

Keep it away from heat, open flames, and potential ignition sources. It should be stored separately from acids, reducing agents, flammable materials, and other incompatible substances.

Ensure the storage area is equipped with explosion-proof ventilation and lighting, with switches placed outside the storage room for safety.

Handle the product with care to prevent damage to the packaging or containers. Avoid impact, vibration, or rough handling, and always use appropriate personal protective equipment (PPE) during transportation and handling. -

Safety Tests

Drop Hammer Sensitivity: Greater than 60 cm

Friction Sensitivity: Greater than 700 kg/cm²

Pressure Vessel Test: 1.8 mm

Self-Accelerating Decomposition Temperature (SADT): 80°C

Alarm Temperature: 75°C