Pendulum Impact Testing Machine for Metals, Dynamic Tear Testing (DT Test)

Request a Quote

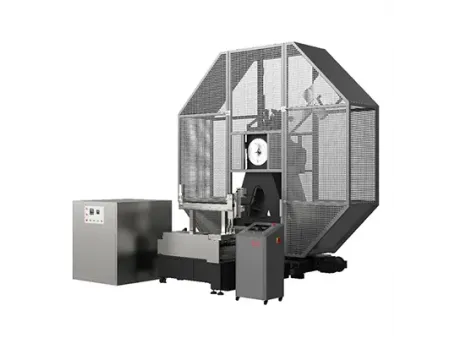

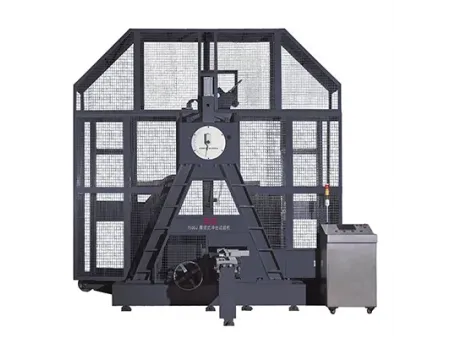

PIT-E Series (5000J-7500J)

The pendulum impact testing machine is specifically designed for dynamic tear (DT) testing of metallic materials.

Standards

ASTM E604, GB/T 5482

Features

- Fully automated operation

This impact testing machine configuration supports automatic specimen feeding, impact execution, pendulum lifting, and specimen removal, enabling a true fully automated workflow. - Heavy-duty base and frame

A high-strength carbon-steel base combined with a 300x300 H-beam steel frame delivers outstanding rigidity and structural stability.This architecture effectively absorbs impact-induced vibration. The specimen anvil is manufactured from 45# steel (forged and tempered), offering excellent strength and high measurement accuracy. - High-strength pendulum

Engineered for high axial and lateral stiffness, the pendulum ensures consistent and reliable energy transfer during each impact. The swinging pendulum assembly includes: Pendulum body, arm, hook, and striker. The pendulum arm is machined from 45# steel into an H-beam profile. The body and the arm are fully tempered for enhanced structural integrity. The striker is made from hardened tool steel, reaching a hardness of ~62 HRC, providing exceptional wear resistance. - Three impact energy levels

Multiple selectable energy levels can be achieved without changing the pendulum, offering greater convenience and improved test efficiency. - Automated specimen feeding and positioning system

A system designed for fast, precise, and safe specimen handling Workflow:

① Specimen placed on the feed table;

② Positioning cylinder sets specimen length;

③ Transfer cylinder moves the specimen to the pre-support zone;

④ Loading cylinder pushes the specimen into the final test position;

⑤ All cylinders automatically return to default positions - Robust specimen support assembly

A combined support-block and anvil structure provides high load-bearing capability.The anvil is produced from hardened Cr-Mn steel (58-62 HRC), ensuring stable support under high-energy impact conditions. - Siemens-based control platform

A Siemens S7-200 PLC provides reliable control logic, a high degree of automation, reduced operator workload, and improved productivity and operational safety.

Specifications

| Model | | |

| Maximum impact energy | 5000J | 7500J |

| Angle of striking | 135° | 135° |

| Angle resolution | 0.1° | 0.1° |

| Distance from the axis of support to the center of percussion | 1380 | 1500 |

| Velocity of striking | 6.797m/s | 7.087m/s |

| Support span, mm | 165±0.8 | 165±0.8, 406±1.5, 500±1.5, 600±1.5 (adjustable) |

| Radius of curvature of supports, mm | 12.7±0.8 | 12.7±0.8, 35±0.5 |

| Angle of taper of supports | 11°±1° | 11°±1° |

| Radius of striking edge, mm | 12.7±0.8 | 12.7±0.8, 38±0.5 |

| Angle of striking tip | 30°±1° | 30°±1° |

| Thickness of striking tip, mm | 37 | 37 |

| Specimen dimension, mm | (180±2) x (40±1) x (5~16) | Standard specimen: 180x40x5~16 Non-standard specimen: 460x120x25, 550x160x32, 650x200x40 |

| Weight | 6500kg | 10000kg |

| Dimension, mm | 3700x2350x3800 | 3800 x 2905 x 3880 |

| Power requirements | 3-phase, 5-line, AC 380V±10% 50Hz 850W | 3-phase, 5-line, AC 380V±10% 50Hz 5Kw |