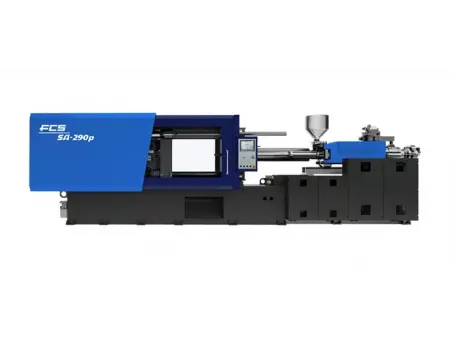

Bucket Injection Molding Machine

The bucket injection molding machine features a servo-hydraulic system for producing bucket containers. This plastic molding equipment features a robust, dual-axis support structure without welds, enhancing the stability and accuracy needed for precise molding. It controls temperatures with exceptional precision within ±1℃ using a PID system and operates with a fast scanning cycle under 1ms. The clamping force is capable of reaching between 220 to 1,000 tons.

- Injection stroke: 230mm-550mm

- Injection capacity: 411g-4757g

- Injection pressure: 1692kgf/cm²-1764kgf/cm²

- Injection rate: 354g/s-1410g/s

- Clamping force 220tonf-1000tonf

- Clamping stroke 500mm-1300mm

- Ejector force 6.7tonf-25tonf

- Pump motor power 41.6kW-63.5kW 63.5kW 41.6kW

- Electric heating power 10.8kW-61.8kW

- Drive system hydraulic

Suitable for producing plastic paint buckets, chemical barrels, household water buckets, and various types of plastic baskets and containers.

Samples of Plastic Injection Molded Parts- Injection molding of disposable tableware

Features a rigid mold plate that reduces elastic deformation and lowers the required clamping force. It includes high-speed proportional valves for faster response, more accurate positioning, and reduced cycle times.

Equipped with a high-performance servo system that quickly responds to up to 40 m/s and reduces energy usage by 30%-70%. Its modular design makes maintenance easy.

The structure uses non-welded pipelines, decreasing the risk of oil leaks and enhancing the plastic processing machine's durability and cleanliness.

The dual linear rails support the injection unit, minimizing friction and improving accuracy. The hydraulic injection molding machine uses a medium-inertia, single-cylinder injection mechanism for quick and consistent operation.

- Includes a KEBA control system for efficient management.

- Features a fast action scanning period of less than 1 ms.

- Ergonomically designed for comfortable use.

- Uses infrared nano-heating rings that heat up quickly and maintain temperature effectively, achieving over 30% energy savings.

- Employs PID temperature control to maintain tight temperature accuracy within ±1°C.

- The high L/D ratio screw enhances mixing and plasticizing efficiency.

- Models SA-650p and above are equipped with automatic feeding, enabling shorter molding cycles through dual-circuit actions.

| Model | UNIT | |||||

| Injection Unit | Type | - | 770 | 1100 | 7600e | 8800e |

| Screw diameter | mm | 50 | 60 | 100 | 110 | |

| Screw stroke | mm | 230 | 230 | 550 | 550 | |

| Theoretical shot volume | cm³ | 452 | 650 | 4320 | 5227 | |

| Shot weight of injection (PS) | gram | 411 | 592 | 3931 | 4757 | |

| Injection pressure | kgf/cm² | 1710 | 1736 | 1764 | 1692 | |

| Injection speed | mm/sec | 195 | 165 | 170 | 160 | |

| Injection rate | cm³/sec | 389 | 478 | 1343 | 1549 | |

| Mold Clamping Unit | Mold clamping force | tonf | 220 | 330 | 700 | 1000 |

| Mold clamping stroke | mm | 500 | 640 | 1000 | 1300 | |

| Mold thickness | mm | 200~550 | 220~610 | 400~1000 | 500~1000 | |

| Tie bar spacing (H×V) | mm | 530×470 | 630×585 | 910×820 | 1090×950 | |

| Mold platen (H×V) | mm | 800×800 | 940×900 | 1320×1320 | 1540×1400 | |

| Ejector stroke | mm | 135 | 140 | 175 | 270 | |

| Ejector force | tonf | 6.7 | 8.8 | 13.0 | 25.0 | |

| Electrical Equipment | Max. pump driving motor | kW(380V) | 41.6 | 53 | 63.5 53 53 | 63.5 63.5 41.6 |

| Heater capacity | kW | 20.4 | 32.6 | 57.1 | 61.8 | |

| General | Machine dimensions (L×W×H) | mm | 6320×1550×2050 | 6950×1710×2125 | 9700×2220×2180 | 11200×2800×2450 |

| Oil tank capacity | liter | 420 | 500 | 880 | 1050 | |

| Machine weight | ton | 10.8 | 12.8 | 29 | 48.2 |