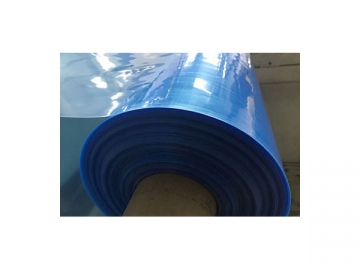

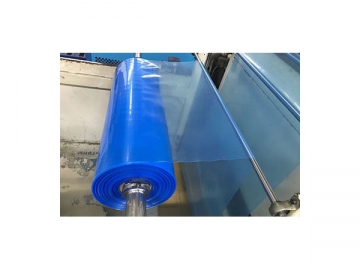

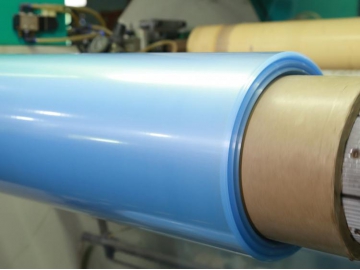

Plastic Sheet Film Roll

We provide plastic sheet film roll for use in various plastic molding processes, including:

1. Automotive parts: automotive door water shield, clear plastic car seat cover, seat inside foam cover

2. Plastic sheet film roll for vacuum forming machine

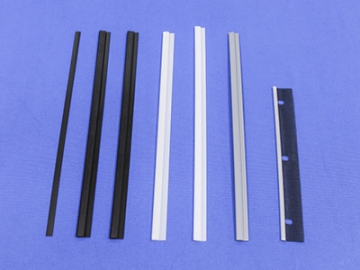

LDPE, HDPE, PP, MDPE, IXPE, PET, needle punched non-woven fabrics

Thickness 0.02 ~0.20mm. Weight, shape and size specification can be customized (we only have white PET needle punched non-woven fabrics).

Blowing film → rolling

We are ISO/TS16949 auto quality certified, and our PE, PP, and MDPE plastic sheet film rolls are non-toxic, odorless, durable and feature an outstanding toughness and tear resistance. They can be used for more than 3 years, while the IXPE and PET plastic sheet film rolls can be used for more than 2 years. We will test the appearance and density of each batch before they leave the factory, and only those deemed qualified will be sent out.

| Item | Technical standard | Testing methods | Testing standard | |

| Appearance | It is homogeneous, transparent, glossy, and sticky solid | visual inspection | ―― | |

| Temperature resistance | No flowing or breaking phenomenon | 90℃ | ||

| Corrosion | Galvanized sheet and aluminum sheet | No scar or corrosion phenomenon | Soak 3/4 of it in distilled water at 38 ℃ for 168h | ASTM D925 |

| Copper sheet | No discoloration, etching or corrosion | 70±2℃*168h | ||

| Odor | Sample:100mm×100mm×0.08mm | TSM 0505G:2014 | ||

| Shelf Life | 12 months | 5~35℃,Put it in a cool, dry room | ―― | |

Index

LDPE film, plastic sheet roll, HDPE film roll, PP film, needle punch nonwoven fabric