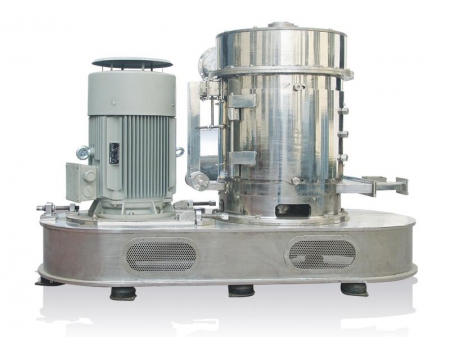

Vortex Mill

Our vortex mills can be used for normal temperature pulverizing of thermosensitive materials, like rice, cassava fiber, tobacco stems, soy protein, silica gel, magnesium metal, etc.

This powder grinding mill is also extensively used in industries like chemical engineering, plastic product manufacturing, non-metallic mines, non ferrous metal product manufacturing, etc.

| Model \ Data | ||||

| Power of rotor(kw) | 45-55 | 75-90 | 132-160 | 220-250 |

| Fineness(um) | 5~400 | 5~400 | 5~400 | 5~400 |

| Evaporative capacity(kg H2O/h) | 80~120 | 200~300 | 500~1000 | 1000~2000 |

| Capacity (kw) | 0.1~1.2 | 0.2~2.5 | 0.5~5 | 1~10 |

- The rotor blades and internal lining are made from high-wear-resistant materials, ensuring minimal wear and preventing contamination, making it ideal for processing medium-hard materials

- The rotor assembly undergoes dynamic balancing for stable performance, while the base is supported by vibration-damping pads, resulting in low vibration and noise during operation

- Can be equipped with an air classification system, allowing the production of materials with different particle sizes

- Low energy consumption and high output make it particularly suitable for processing products with lower added value

- The main machine could be matched with motors of different powers.

- Automatic feed back control; simple operation, convenient maintenance and easy clean.

The rotor of this grinding mill is composed of several grinding disc and blades. While the rotor is rotating at extremely high speed, it realizes crushing and pulverizing for materials. And the air stream, which is generated for the high speed rotation of rotor, will also help crush and pulverize materials.

1. Feeding system

2. Pulverizing system

3. Cyclonic collector

4. Bag collector

5. Induced draft fan

1. Feeding system

2. Pulverizing system

3. Screw conveyor for material feed back

4. Classification system

5. Cyclone dust collector

6. Pulsed dust collection

7. Induced draft fan

1. Air heating system

2. Material feeding system

3. Vortex mill (main machine)

4. Cyclonic collector

5. Pulsed dust collection

6. Air blower

1. Feeding system

2. Pulverizing system

3. Cyclonic collector

4. Bag collector

5. Screw conveyor

6. Induced draft fan