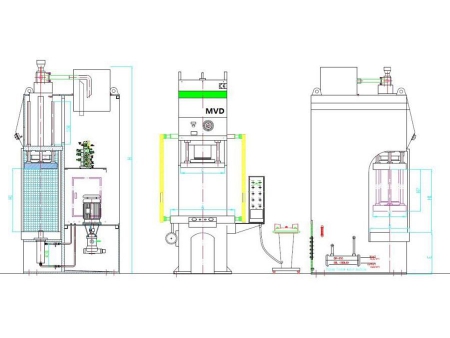

C-Frame High Speed Hydraulic Press

Request a Quote

with HMI Control

Characteristics

- C-frame structure enjoys outstanding rigidity. Each press is designed through Finite Element Structural Analysis and optimization to assure high strength and rigidity.

- Main cylinder is specially designed for high velocity, motor uses less power, high ascending and descending speed, increased efficiency. (Such technology is introduced from Taiwan.)

- C-frame are made of high strength alloy steel with hard chromium plated surface featuring good wear-resistance.

- The main hydraulic and electric parts adopt brand-name components from Japan, France, Germany and Taiwan, so the machine enjoys high reliable performance.

- Mitsubishi PLC Touch Screen (HMI) integrated control. There are 3 operation manners, adjustable, manual and semi-automatic.

- Designed with adjustable drawing speed, the machine is applicable for various thickness metalworking and deep drawing.

- The Press fully meets CE safety requirements.

- The slide has fast speed and high productive efficiency.

High Reliability

- Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,

- The entire equipment totally security (according to EN292:1994, EN60204:1994 and NR12) and defined as Level 4 of safety.

- Intrinsic hydraulic safety valve block with redundant control and dynamic monitoring carried out by a security interface

- Right side protection: vertical door, pneumatic actuating, made of aluminium frame and polycarbonate transparate plates.

Applications

Deep draw press is applied in production techniques, like deep drawing, stamping, cutting, bending, flanging of metal sheet.

Particularly applied in the following industries:

- Automobile Industry: steel ring, vehicle body, chasis, axle housing, fuel tank, door and many more.

- Household Appliance Industry: Components for air conditioner, refrigerator, washing machine, electric cooker etc.

- Kitchen Ware Industry: stainless steel utensil, gas cylinder, stainless steel sink, cooking bench, etc.

- Aluminum Cookware.

- Steel Plate Straightening & Bending

Control function

- Double hand action button Emergency Button 4-Category

- Control panel with manual override to change and tool setting;

- Course setting for inductive sensor with fine tuning;

- Monitor the Press working process

- limitation of working stroke, for particular drawing operations

- with upper triple action (both active and passive)

- with drawing from the bottom

- Light curtain, protection grid and monitored block (according to local regulations);

Standard Equipment

- Delta HMI (Human Machine Interface)

- PLC (Programmable Logic Controller)

- Ruler Transducer position (adjustable HMI);

- Germany Bosch-Rexroth Hydraulic

- Telemecanique/Schneider Electrics

- Hydraulic and Electrical overload protection

- Forced air cooling system

- Safety light curtain protection

- Side metal barrier protection

Optional

- Die Change Trolley

- Mould Hydraulic clamping

- Oil Cooler Machine

- Safety Light Curtain

- Pressure transducer (adjustable HMI);

- Cushion Device for anti-shock while stamping

- Stamping Dampers for shock proof while stamping

- Air breathing design as per request

Specifications

| Model | HPP-40 | HPP-63 | HPP-80 | HPP1-100 | HPP-100A | HPP-160 | ||||

| Capacity | kN | 400 | 630 | 800 | 1000 | 1000 | 1600 | |||

| Return Force | kN | 80 | 69 | 115 | 135 | 135 | 210 | |||

| Max. Hydraulic Pressure | mm | 25 | 25 | 25.5 | 25 | 25 | 26 | |||

| Slide Stroke | mm | 400 | 500 | 500 | 500 | 500 | 560 | |||

| Throat Depth | kN | 280 | 320 | 320 | 380 | 500 | 400 | |||

| Shut Height | Straightening | mm | 600 | 700 | 700 | 700 | 750 | 900 | ||

| Pressing | mm | 800 | 1000 | 1000 | 1000 | 1100 | 1120 | |||

| Slide Speed | Idle Stroke | mm/s | 110 | 130 | 70 | 75 | 75 | 75 | ||

| Pressing | mm/s | 9-22 | 6-14 | 8-18 | 7-15 | 7-15 | 7-15 | |||

| Return | mm/s | 110 | 125 | 100 | 90 | 90 | 110 | |||

| Bolster | LR | Straightening | mm | 1100 | 1200 | 1200 | 1400 | 2000 | 1600 | |

| Pressing | mm | 620 | 720 | 720 | 850 | 1000 | 1000 | |||

| FB | mm | 520 | 600 | 600 | 720 | 800 | 720 | |||

| Slide | LR | mm | 560 | 620 | 700 | 700 | 700 | 700 | ||

| FB | mm | 420 | 460 | 500 | 500 | 500 | 500 | |||

| Bolster Height Above Floor | mm | 720 | 750 | 780 | 820 | 820 | 600 | |||

| Bolster Opening | mm | φ120 | φ150 | φ180 | φ200 | φ200 | / | |||

| Outline Size | LR | Straightening | mm | 1250 | 1280 | 1350 | 1400 | 2000 | 1600 | |

| Pressing | mm | 1250 | 1280 | 1350 | 1400 | 1400 | 1600 | |||

| FB | mm | 1300 | 1450 | 1550 | 1900 | 2250 | 2300 | |||

| Above Floor | Straightening | mm | 2600 | 2750 | 2860 | 2920 | 3020 | 3200 | ||

| Pressing | mm | 2800 | 3050 | 3160 | 3220 | 3370 | 3350 | |||

| Below Floor | mm | / | / | / | / | / | / | |||

| Main Motor Power | kW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 15 | |||

| Weight | Straightening | kg | 2800 | 4200 | 5300 | 6400 | 7400 | 11000 | ||

| Pressing | kg | 3000 | 4500 | 5500 | 6800 | 7800 | 12000 | |||

Configuration list

| No. | Item | Standard MAKE | High Standard MAKE |

| 1 | PLC | Mitsubishi | Siemens |

| 2 | Motor | WanNan/China top brand | Siemens / Rexroth |

| 3 | Pump | Anson/Taiwan, Yuken/Japan | Siemens / Rexroth |

| 4 | Servo Pump | DAIKIN/Japan | DAIKIN/Japan |

| 5 | Directional Valve | Yuken/Japan | Atos/Italy, Rexroth |

| 6 | Proportional Valve) | Yuken/Japan | Atos/Italy, Rexroth |

| 7 | Cartridge Valve | Jeou Gang/Taiwan,SUN/USA | SUN, Atos, Rexroth |

| 8 | Prefill Valve | TAI COLN/Taiwan | Atos/Italy, Rexroth |

| 9 | Electric Units | Schneider/France | Schneider/France |

| 10 | Light Curtain | LNTECH with CE Mark | LNTECH with CE Mark |

| 11 | Touch Screen(HMI)9 | Weinview/Taiwan | Siemens |

| 12 | Pressure Gauge | SKON/Taiwan | S KON/Taiwan |

| 13 | Hydraulic Manifold | MADE IN TAIWAN | MADE IN TAIWAN |

| No worse quality components are adopted in ACCURL Presses. | |||

Detailed Pictures