Cloth Media Disc Filter, GLK

- Filter pond: square tank, steel concrete structure or carbon steel box, stainless steel box can be used according to the needs of users.

- Filter disc: stainless steel filter cloth and plastic framework.

- Backwashing component: cleaning pump, reducer and chain wheel transmission mechanism driving the filter disc to rotate.

- Sludge discharge device: collect sludge at the bottom of the filter disc to facilitate the sedimentation, collection and discharge of sludge.

Cloth Media Disc Filter with Integrated Metal Tank

| Model | | | |

| Flow rate | 15m³/h | 25m³/h | 40m³/h |

| Disc diameter | 1000mm | 1600mm | 2000mm |

| Number of disc | 2-8 pcs | 2-10 pcs | 2-10 pcs |

| Filtration area | 1.7m²/single disc | 2.5m²/single disc | 4.5m²/single disc |

| Filtration speed | 8-15m | 8-15m | 8-15m |

| Filter influent SS (suspended solids) | ≤40mg/L | ≤40mg/L | ≤40mg/L |

| Filter effluent SS (suspended solids) | ≤10mg/L | ≤10mg/L | ≤10mg/L |

| Disc material | Reinforced plastic | Reinforced plastic | Reinforced plastic |

| Fiber cloth | Fiber filter cloth | Fiber filter cloth | Fiber filter cloth |

| Influent central tube material | Stainless steel | Stainless steel | Stainless steel |

| Filter tank body material | Stainless steel/carbon steel | Stainless steel/carbon steel | Stainless steel/carbon steel |

| Drive motor power | 0.37 kW | 0.37 kW | 0.37 kW |

| Backwash pump power | 2.2 kW | 2.2 kW | 2.2 kW |

| Backwash flow rate | 25m³/h | 25m³/h | 25m³/h |

| Cleaning cycle | 0-300min | 0-300min | 0-300min |

| Cleaning time | 2min/dual disc | 2min/dual disc | 2min/dual disc |

| Head loss | 250mm | 250mm | 300mm |

| Filtration method | Gravity filtration | Gravity filtration | Gravity filtration |

| Dimensions | 3550×1260×1750 | 4800×1800×2500 | 6000×2310×3000 |

*For larger flow, different water quality and other technical parameters, please consult Xuyang for details.

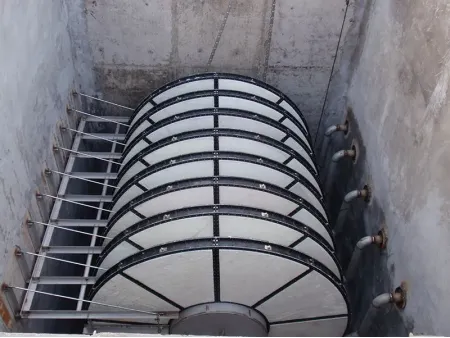

Cloth Media Disc Filter with Concrete Tank

| Model | | | | | |

| Flow rate | 15m³/h/single disc | 25m³/h/single disc | 40m³/h/single disc | 65m³/h/single disc | 100m³/h/single disc |

| Disc diameter | 1000mm | 1600mm | 2000mm | 2500mm | 3000mm |

| Number of disc | 2-8 pcs | 2-10 pcs | 2-10 pcs | 2-12 pcs | 2-12 pcs |

| Filtration area | 1.7m²/single disc | 2.5m²/single disc | 4.5m²/single disc | 7.5m²/single disc | 12.0m²/single disc |

| Filtration speed | 8-15m | 8-15m | 8-15m | 8-15m | 8-15m |

| Filter influent SS (suspended solids) | ≤40mg/L | ≤40mg/L | ≤40mg/L | ≤40mg/L | ≤40mg/L |

| Filter effluent SS (suspended solids) | ≤10mg/L | ≤10mg/L | ≤10mg/L | ≤10mg/L | ≤10mg/L |

| Disc material | Reinforced plastic | Reinforced plastic | Reinforced plastic | Reinforced plastic | Reinforced plastic |

| Fiber cloth | Fiber filter cloth | Fiber filter cloth | Fiber filter cloth | Fiber filter cloth | Fiber filter cloth |

| Influent central tube material | Stainless steel | Stainless steel | Stainless steel | Stainless steel | Stainless steel |

| Filter tank body material | Concrete | Concrete | Concrete | Concrete | Concrete |

| Drive motor power | 0.37 kW | 0.37 kW | 0.55 kW | 0.55 kW | 0.55 kW |

| Backwash pump power | 2.2 kW | 3.0 kW | 3.0 kW | 4.0 kW | 4.0 kW |

| Backwash flow rate | 25m³/h | 25m³/h | 25m³/h | 25m³/h | 25m³/h |

| Cleaning cycle | 0-360min | 0-360min | 0-360min | 0-360min | 0-360min |

| Cleaning time | 2min/dual disc | 2min/dual disc | 2min/dual disc | 2min/dual disc | 2min/dual disc |

| Head loss | 250mm | 250mm | 300mm | 350mm | 350mm |

| Filtration method | Gravity filtration | Gravity filtration | Gravity filtration | Gravity filtration | Gravity filtration |

| Dimensions | 8300×2200×2200 | 8700×2800×2200 | 8750×3200×2600 | 10100×3800×2700 | 10200×4300×2800 |

*For larger flow, different water quality and other technical parameters, please consult Xuyang for details.

Working principleThis rotary disc filter consists of multiple filter discs arranged horizontally, each with a fan-shaped filter plate covered by a fiber filter cloth with 10 μm openings. Its operating procedures involve filtration, backwash and sludge discharge.

1. Filtration

- Sewage travels to the filter tank through gravitational force, and a water distribution weir is positioned within the tank. The filter cloth is entirely submerged and allows the sewage to flow through from the outside in. Then, with gravity, the fluid travels from the outlet weir and out of the filtration system as one consistent process.

2. Cleaning

- Sewage travels to the filter tank through gravitational force, and a water distribution weir is positioned within the tank. The filter cloth is entirely submerged and allows the sewage to flow through from the outside in. Then, with gravity, the fluid travels from the outlet weir and out of the filtration system as one consistent process.

- To ensure efficient cleaning operations, an alternate cleaning mode is used. The suction pump works continuously, switching automatically between two filter discs every two cycles. In the event of decreased water quality or a rapid increase of liquid levels in the tank, all backwash pumps will automatically activate at the same time to clean several groups of filter discs until normal operations are restored.

-

3. Sludge discharge system

This sludge discharge system has been constructed with a funnel-shaped container base. By collecting the sludge at the bottom, this minimises the amount of build-up on the filter material, meaning the filtration process is extended and the amount of backwash water needed is reduced. The sludge pump sends the sludge back to the wastewater treatment network through the sludge discharge pipe which has been perforated at the bottom of the tank. The interval and duration of the sludge discharge can all be adjusted.

- The quality of the wastewater is stable and the filtration is effective, allowing it to withstand an influx of up to 60-80mg/L of suspended solids (SS). When the SS input is at or below 40mg/L, the effluent SS output is kept to 10mg/L or less.

- With its minimal size and low energy consumption, this filter helps to reduce both space and costs.

- The waterhead loss remains minimal, guaranteeing that the water flow and pressure stay consistent, with the head loss between the states not exceeding 300 mm.

- Automation can help reduce manual labor and the associated costs.

- The use of modular design in combination with swift filter cloth replacement can dramatically reduce maintenance and repair expenditure.

- This filter features filter cloth with a special weaving technology, providing increased resilience and superior filtration precision. The microfilter diameter range is 5-20 μm and can be chosen depending on the need. This allows for an effective filtering of small particles and an improved quality of the water. The fiber surface is smooth and prevents dirt build-up, while also featuring excellent corrosion resistance and the prevention of mildew. These traits ensure the longevity of the filter cloth and stability in water quality.