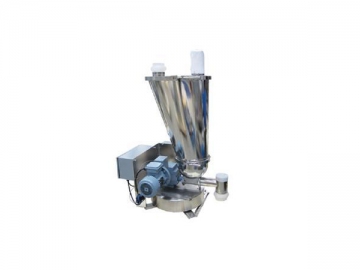

Gob Feeder, BLD660/910 Series

Gob Feeder, BLD660

The BLD660 series gob feeder is designed on the basis of the aging D41-66 through a series of improvements and innovations. It has become a standard configuration for the gob forming system of many popular models of individual section machines. It supports single gob and double gob production.

Advantages

Connecting rod style plunger and shear mechanisms using linear bearings

Electric synchronous drive unit

Air spring utilized for shear mechanism

Revolving tube mechanism controlled by a variable frequency drive to ensure stepless speed adjustment

Independent and reliable Bijur lubrication system

Gob Feeder, BLD910

This range of gob feeder is compatible with single gob and double gob glass container forming machines with 8 or 10 section configurations.

Advantages

Compact cylindrical epicyclic gearbox supporting 360° differential regulation

Employ linear bearings for the balanced type plunger mechanism

The shearing mechanism featuring enclosed gear and oil bath lubrication

New air spring for the high speed shearing mechanism

Positive infinitely variable system is employed for the revolving tube mechanism

| Model | Spout Size | Spout depth | Orifice Ring | Cavity | Capacity (t/day) |

| 360 (14") | 152 (6") | 5" | SG, DG76 | 5-25 | |

| 190 (7-1/2") | 5" | SG, DG76 | 5-25 | ||

| 410 (16") | 190 (7-1/2") | 5" | SG, DG76 | 10-25 | |

| 203 (8") | 5" | SG, DG76 | 12-30 | ||

| 6" | SG, DG76 | 12-30 | |||

| 7" | SG, DG110 | 12-30 | |||

| 460 (18") | 203 (8") | 7", 8" | SG, DG, TG | 15-35 | |

| 460 (18") | 210 (8-1/4") | 7", 8" | SG, DG, TG | 15-40 | |

| 230 (9") | 7", 8" | SG, DG, TG | 15-45 | ||

| 254 (10") | 7", 8" | SG, DG, TG | 25-60 | ||

| 560 (22") | 210 (8-1/4") | 7". 8", 10" | SG, DG, TG | 25-50 | |

| 230 (9") | 7". 8", 10" | SG, DG, TG | 25-60 | ||

| 254 (10") | 7". 8", 10" | SG, DG, TG | 35-70 | ||

| 278 (11") | 7". 8", 10" | SG, DG, TG | 45-80 | ||

| 610 (24") | 278 (11") | 8", 10", 11" | SG, DG, TG | 50-100 | |

| 330 (13") | 8", 10", 11" | SG, DG, TG | 50-120 | ||

| Speed Range | 10 ~ 90 cuts per minutes | 25 ~ 120 cuts per minutes |

| Weight Range | Single gob: 30g to 2000g, Double gob: 30g to 500g | Single gob: 100g to 2300g, Double gob: 50g to 1100g |

| Configurations | Individual plunger mechanism with air assisting system | Balanced type plunger mechanism |

| Variable speed revolving tube with bevel gear drive | Variable speed revolving tube with bevel gear drive | |

| Arcuate shear mechanism | Arcuate shear mechanism with enclosed gear | |

| Safety auto-retracting shear blade | Safety auto-retracting shear blade | |

| Shearing mechanism with air spring | High speed shearing mechanism with air spring | |

| Automatic lubrication system linked to IS machine lubrication system | Automatic lubrication system linked to IS machine lubrication system | |

| Accessories | Accessories | |

| Shear blade alignment fixture | Shear Blade alignment fixture | |

| Epicyclic gearbox supporting 360° differential adjustment |