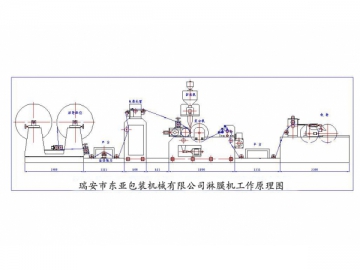

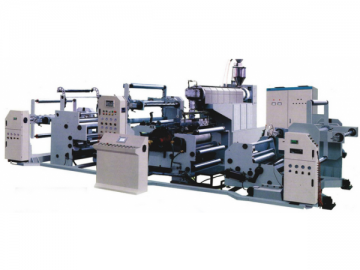

High Speed Film Laminating Machine

MainTechnical Parameter

| Model | SJ-85-1350 | SJ-90-1650 |

| Width of finished product | 600 | 1100 |

| Max. compounding speed | 50 | 50 |

| Thickness of lamination | 0.01 | 0.01 |

| L/D ratio of screw | 28:1 | 28:1 |

| Max. diameter for unwinding and rewinding | | |

| Overall dimension | 12500×7000× | 13000×8000× |

| Power | 75kw | 95kw |

| Applicable for basic material | BOPP, BOPET, BOPA, CPP, CPE | |

Mainspec.

material PP, PE, PAPER,BOPP BOPET BOPA CPP CPE original material PP, PE or

originalmaterial spec width

productivity 100meter/min(

extruder screwФ

Ф

1. Extruder:

screw

screwmaterial 38CRMOALalloy steel,treated by nitrification

cylinderpipe heating stainlesssteel,electriccapacity 35KW

drivemotor 30KW(

extruder

structure

horizontal

horizontal moving 2HPmotor,

vertical

vertical

3 phase connect

material

heating fashion stainlesssteel heating board,electric capacity6KW

temperature

mould material treatedsteel,surface polishing

3.Laminating equipment:

type

structure

cool

surfacetreated and polishing,double inner shell

singleflow volution cool water,cool water screw connector as attachment

silicon

surfacetreated by silicon rubber,

innercool water,screw connector

fashion

back

surfacetreated and polishing,inner cool water,screw connector

spread

idler

drive motor 7KW(screen changer)

4.Sidecutting equipment:

width

diameter Ф

6. Electric, air pressurecontrol and equipment operation(

laminating equipment airpressure control 、operation switch etc

tap tensioncontrol switch、air correct system

rewinding equipment drivecontrol and operation switch、rewinding switch

airpressure control equipment、operation switch etc