Other Forgings

Apart from forgings for thermal power, hydropower, and shipbuilding, TongYu also provides custom forgings for metallurgy, mining, nuclear power, and aerospace, among other industries.

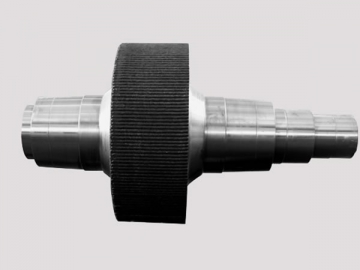

Forging parts range: ring gear, torsion bar, roller shaft, blower shaft, upper roller, crusher roller, bushing, roller, dies, rotors for sugar cane juicer, shaft of roller press, etc.

TongYu has become one of the largest manufacturers of large forgings and castings. We provide various for thermal power, hydropower, and shipbuilding industries, etc.

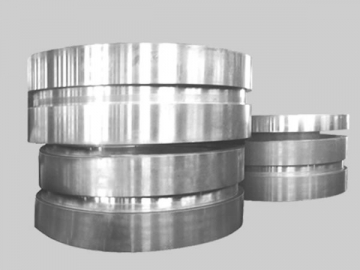

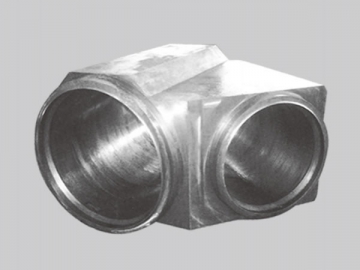

Case ShowUpper roller

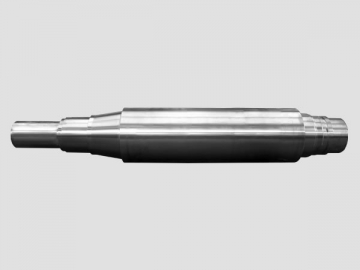

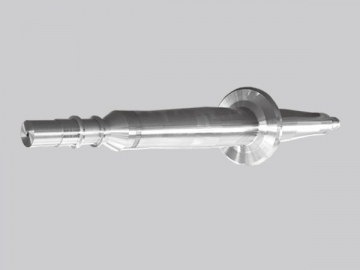

Torsion bar

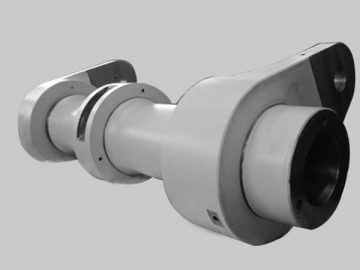

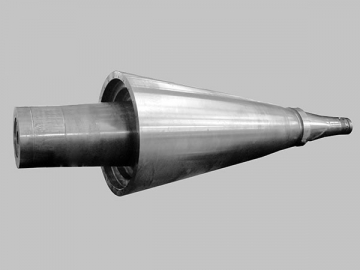

Rotor for sugar cane juicer

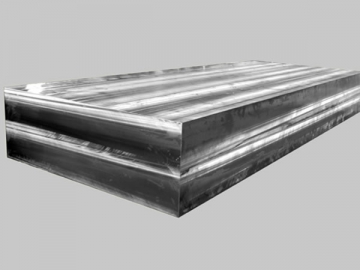

Forged dies

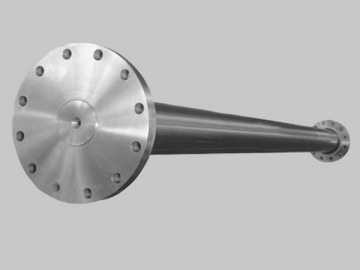

Blower shaft

Blower shaft

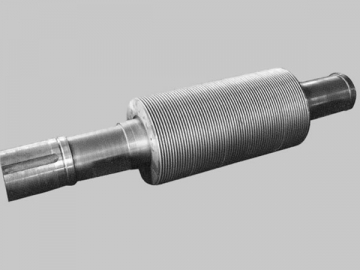

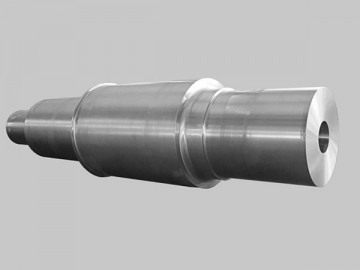

Roller shaft

Roller

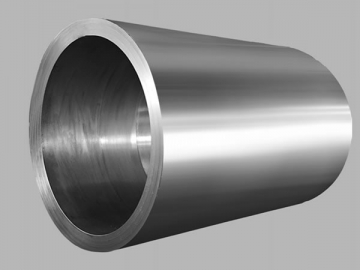

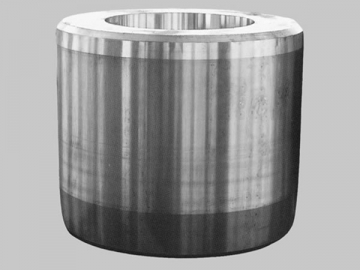

Shaft sleeve

Shaft for roller press

Taper bush

Ring gears

Product range:

3-way pipe connectors, stepped shafts, flanged shafts, hydro turbine main shaft, crusher shaft, roller press shaft, steel rollers, steel bushes, etc.

Free forging means a processing technique to get the forgings with required shapes, dimensions and certain mechanical properties by exerting force on metals to let it deformed at any direction without any limitation. It mainly consists of upsetting, stretching, punching, hole expanding, bending, and twisting steps. Free forgings include shaft forgings, strip forgings, plate forgings, forged rings, barrel forgings, bowl-shaped forgings, etc.

We will draw up the manufacturing techniques to guarantee the production cycle and quality according to clients' requirements.

Materials

Various carbon steels, carbon manganese steel , alloy steel, stainless steel, tool steels, mold steels, and heat-resistance steels, like 25, 35, 45, 55, 16Mn, 20Mn, 40Mn, 50Mn, 20Mn5, 28Mn6, 20SiMn, 35SiMn, 40Cr, 25CrMo, 35CrMo, 42CrMo, 20MnMoNb, 20MnMo, 20CrMnMo, 20CrNiMo, F11, F12, F22, F91, F92, 17CrNiMo6, 18CrNiMo7-6, 21CrMo10, 34CrNiMo6, 30CrNiMo8, 34CrNi3Mo, 34CrNi3MoV, 5CrNiMo, 5CrMnMo, 60CrMnMo, 55NiCrMoV7, AISI 4340, H11, H13, 70Cr3Mo, and 9Cr2Mo, etc.

Manufacturing Process

Smelting – Forging – Heat Treatment (roughing – quenching and tempering) – Machining – Packaging

Quality Control

1. During the smelting process, strict control is required both for the prescribed elements (21CrMo10), and for some harmful elements and gas, like P, S, Pb, Sn, As, Sb, Bi, and H, O, N.

2. For pressure vessels with special requirements, double vacuum smelting or electroslag remelting techniques are required to guarantee their purity, chemical element, and gas content.

3. Strict forging technique is required to meet the nondestructive testing requirements.

4. After heat treatment, the free forgings will possess high comprehensive mechanical properties, uniform structure, and large grain size.

5. CNC equipment is employed for finishing line to ensure the forgings' precision.

6. All of the parameters of our custom forgings are in conformity with national, European, and America standards, like JB/T6397, JB/T6396, JB/T6908, JB/T1270, JB/T1271, JB/T5000, J/T4730, GB/T6402, GB/T11880, GB/T17107, YB/T036, EN10228, EN10083, EN10250, EN10025, SEP1921, SEP1923, JIS G3201, JIS G4053, and ASTM, etc.

7. Special processing requirements are welcomed.