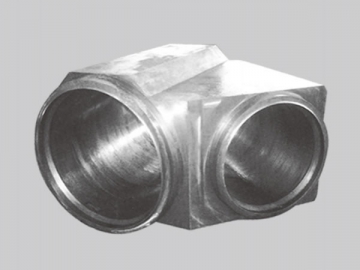

Pressure Vessel Forgings

Pressure vessel is designed to work under certain pressure, temperature and medium for a long time. So in addition to the high requirements on mechanical properties of vessels' material, it has also set standards upon pressure vessels' creep strength, temper embrittlement, corrosion resistance, as well as their performance under high/low temperature according to different applications and environments. Strict inspection like ultrasonic flaw detection, grain size, debris test, and other Metallographic examinations are required for the raw materials, requiring the steels to be of high purity, uniformity, and contain little debris or gas.

Specifications| Common materials | 16Mn, 20MnMo, 20MnMoNb, 20MnNiMo, 14Cr1Mo, 15CrMo, 12Cr1MoV, 12Cr2Mo1, 12Cr2Mo1V, F11, F12, F22, etc. |

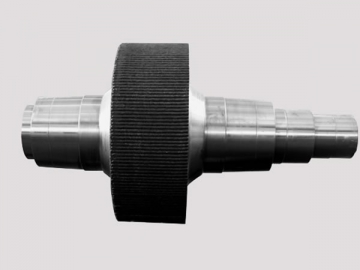

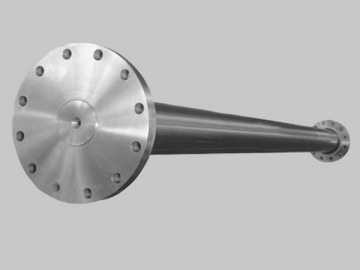

| Applications | tube plates, flanges, hydrogenation reactor cylinder, pressure vessel heads, boiler tubes |

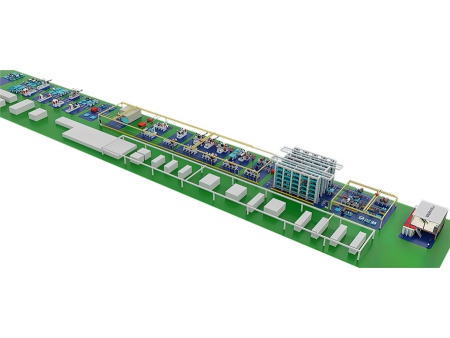

Manufacturing Process

Smelting – Forging – Heat Treatment – Roughing – Quenching and Tempering – Machining – Welding – Machining – Packaging (quenching and tempering is optional for parts of products)

Quality Control

1. Apart from the required chemical elements, we have strictly tested some harmful elements such as P, S, Pb, Sn, As, Sb, and Bi, as well as some gas or non-metallic debris like H, O, and N in the selting process.

2. Double vacuum smelting or electroslag remelting techniques are employed for pressure vessels with special requirements to ensure the high purity, uniform elements, and low gas content of raw materials.

3. Strict forging technique is required to meet the nondestructive testing requirements.

4. We have given the pressure vessel forgings heat treatment to acquire high creep strength, little temper embrittlement, high corrosion resistance, uniform structure, high grain size, as well as great performance under standard/low/high temperature.

5. The finishing line is equipped with advanced CNC equipment to ensure the high precision of our forgings.

6. The ultrasonic flaw detection is conducted in line with the standards' upon pressure vessels. All of the indexes of our pressure vessel forgings are in compliance with JB/T4726, JB/T4727, NB/T47008, and ASME standards.

7. All of the production steps such as smelting, forging, heat treatment, flaw detection, and machining are strictly controlled and inspected in TongYu. The pressure vessel forgings we have produced comply with the national standards and European standards, such as JB/T4726, JB/T4727, NB/T47008, and ASME.

Quality Control

a. Registration Certificate of Steel Forgings for Pressure Vessels

This certificate is issued by the National Standardization Committee on Boilers and Pressure Vessels. Its applicable range: carbon steel and alloy steel forgings, low-alloy steel forgings, stainless steel, and heat-resistance steel forgings

b. MO Certificate from ASME

The material range of MO certificate issued by American Society of Mechanical Engineers (ASME): carbon steel, low-steel alloy, and iron-based materials, with Austenitic stainless steel included. The products it covers include forgings, forged seamless pipes, forged pipes, seamless pipe fittings, flanges, and semi-finished products like plates, steel ingots, steel rings, and hollow forgings.

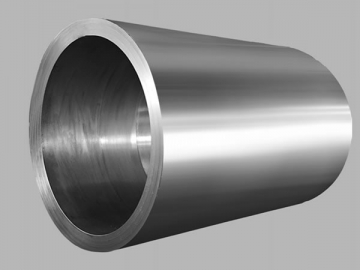

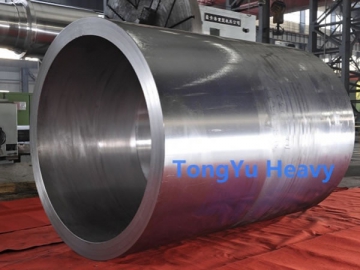

Hydrogenation reactor barrels

Hydrogenation reactor barrels

Hydrogenation reactor barrels