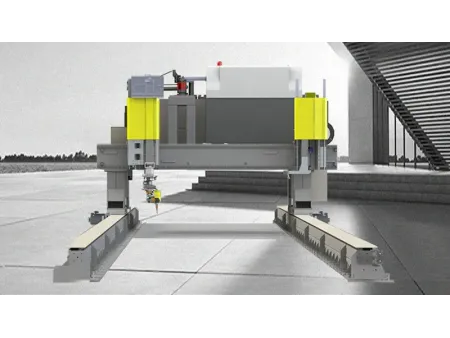

MJ Series 3D Gantry Laser Welding Machine

Laser welding system

Our MJ Series 3D gantry laser welding machine stands out for its versatile welding capabilities, offering partitionable and through-length component welding to address a variety of requirements. Featuring a stable double-gantry optical path system and a versatile compression shaft for varied joint treatments, this equipment boasts automatic focus adjustment for precision. Equipped with the user-friendly Siemens 840DSL CNC system and a comprehensive real-time monitoring system, the MJ series ensures safety while delivering efficient, stable, and precise welding solutions, making it a preferred choice for advanced welding applications.

- X axis500mm-30m

- Y axis500mm-5000mm

- Z axis 200mm-1500mm

Ideal for intricate welding tasks such as the construction of railway locomotive body side walls, end walls, roofs, aircraft skins, and joints.

| Axis travel | X axis | 500mm-30m |

| Y axis | 500mm-5000mm | |

| Z axis | 200mm-1500mm | |

| Repeatability | ±0.02mm | |

| Laser power | 1,000W-20,000W (optional) | |

- Flexible welding methods: Supports both partitionable welding and through-length component welding, accommodating a broad range of welding requirements.

- Stable optical path: Supported by two gantries, the stable optical path ensure consistent laser transmission.

- Adaptable compression device: Comes with a hold-down shaft to cater to diverse joint types, enhancing the flexibility and applicability of the welding process.

- User-friendly CNC system: Utilizes the Siemens 840DSL CNC system, known for its superior dynamic response and precision control, coupled with an easy-to-navigate user interface.

- Comprehensive monitoring: Equipped with a real-time monitoring system for complete oversight of the welding process, ensuring optimal safety and quality.

- Versatile functionality: Capable of performing laserself-fluxing welding, laser welding with wire filler, laser hybrid welding. Offers options for universal compression rollers and includes features for weld tracking and weld quality monitoring, making it a comprehensive solution for varied welding needs.