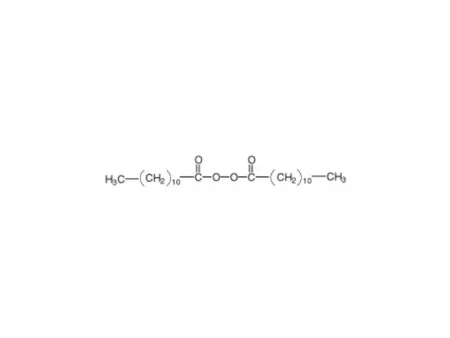

Dilauroyl peroxide (LPO)

Request a Quote

CAS 105-74-8

- Chemical Family Organic Peroxide

- Molecular Formula C₂₄H₄₆O₄

- Molecular Weight 398.6

- EINECS 203-326-3

- UN No. 3106

- Road Transport (ADR) 5.2

- Rail Transport (RID) 5.2

- Sea Transport (IMDG) 5.2

Half-Life Period

(measured in chlorobenzene solution)

- 0.1 hour 99℃

- 1 hour 79℃

- 10 hours 61℃

- Theoretical active oxygen content: 4.01%

- Purity: ≥99.0%

- Self-accelerating decomposition temperature (SADT): 50℃

- Hazardous temperature (Tem): 45℃

- Storage temperature (Ts min/Ts max): --/30℃

- Appearance: White powder or flakes

- Major decomposition products: carbon dioxide, laurate

Applications

Dilauroyl peroxide or LPO is commonly used as a polymerization initiator for various compounds, including ethylene, styrene, vinyl chloride, vinylidene chloride, acrylates, and methacrylates. Its versatility makes it an important component in initiating polymer reactions, especially in the production of plastics and resins.

- LPO is frequently used in polymerization processes, with a working temperature range between 60°C and 75°C. In many cases, it is combined with higher reactivity peroxides, such as Bis(4-tert-butylcyclohexyl) peroxydicarbonate or tert-butyl peroxyneodecanoate (1,1,3,3-tetramethylbutyl ester), to broaden its reactivity range and improve efficiency.

- Although LPO has lower solubility, which often leads to its substitution by peroxynonanoyl, its advantage lies in its ability to be stored at room temperature, making it a practical choice for certain high-pressure polyethylene applications.

- LPO is also a favored initiator for the polymerization of acrylates, with reaction temperatures ranging from 60°C to 90°C. It’s often used as a safer alternative to more toxic compounds, such as azobisisobutyronitrile (AIBN).

- When used alongside compounds like 1,1-Di(tert-butylperoxy)-3,3,5-trimethylcyclohexane (LQ-CH335), LPO significantly enhances initiation effects, making it ideal for various industrial polymerization processes.

Note: Additionally, LPO can be formulated into 40% or 25% aqueous suspensions (LQ-LPO-40W and LQ-LPO-25W), designed for easier handling in reactions involving vinyl chloride.

-

Packaging

LPO is typically packaged in 25 kg fiberboard drums or in 20 kg corrugated boxes, each containing four 5 kg plastic bags. Custom packaging sizes can be arranged based on customer requirements.