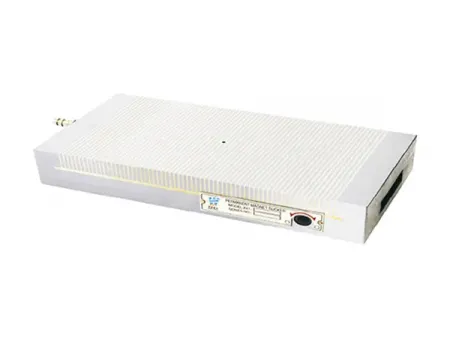

Permanent Magnetic Chuck

Magnetic clamping plates for holding workpieces in machining and metalworking operations

Rectangle steel permanent magnetic chucks offer a reliable clamping solution for grinding, EDM, engraving, and milling machines. Made from wear-resistant brass, steel, and permanent magnets, they maintain precision throughout the machining process without requiring an external power source.

- Magnetic surface retains flatness during on/off switching.

- Strong, permanent magnetic circuit ensures firm clamping without electricity.

- Holding forces available in 80, 100, 120, and 140 N/cm².

- Standard parallelism of 0.03mm/100mm, with customized options achieving 0.005mm/100mm.

| Model | Dimensions (mm) | Net weight (kg) | Pole pitch (mm) | Holding force (N/cm²) | |||

| L | B | H | T | ||||

| | 100 | 100 | 45 | 18 | 3.6 | 0.5 1.5 or 1 3 or 0.5 1 | 140 or 120 or 100 or 80 |

| | 160 | 70 | 45 | 18 | 4 | ||

| | 150 | 150 | 48 | 20 | 8 | ||

| | 200 | 150 | 48 | 20 | 11 | ||

| | 250 | 150 | 48 | 20 | 13.8 | ||

| | 300 | 150 | 48 | 20 | 16.8 | ||

| | 350 | 150 | 48 | 20 | 19.6 | ||

| | 400 | 150 | 53 | 20 | 23.8 | ||

| | 450 | 150 | 53 | 20 | 26.5 | ||

| | 200 | 200 | 48 | 22 | 15 | ||

| | 250 | 200 | 48 | 22 | 18.5 | ||

| | 350 | 200 | 53 | 22 | 28.5 | ||

| | 400 | 200 | 53 | 22 | 31.8 | ||

| | 450 | 200 | 53 | 22 | 39.5 | ||

| | 500 | 250 | 58 | 23 | 53.5 | ||

| | 600 | 300 | 58 | 23 | 77 | ||

Achieving precision in electrical discharge machining (EDM) requires a stable and reliable clamping solution. These permanent magnetic chucks provide a firm hold without the need for external power, making them ideal for grinding, engraving, and EDM applications. Manufactured with wear-resistant brass, steel, and permanent magnets, they ensure durability and accuracy throughout the machining process.

- Integrated oil drainage holes facilitate fast and thorough cleaning, ensuring a strong and precise hold on the workpiece.

- Two pole pitch options (0.5 1.5mm and 1 3mm) accommodate different machining needs, offering versatility in various applications.

| Model | Dimensions (mm) | Holding force (N/cm²) | Weight (kg) | ||

| L | B | H | |||

| | 300 | 150 | 48 | 80 | 16.8 |

| | 350 | 150 | 48 | 80 | 19.6 |

| | 400 | 150 | 52 | 80 | 23.8 |

| | 400 | 200 | 52 | 80 | 31.8 |

Rotary permanent magnetic chucks are designed to provide 360-degree rotation and tilt adjustment, making it easy to position workpieces at the optimal angle. Their strong magnetic hold ensures stability during machining, while the wear-resistant brass, steel, and permanent magnet construction guarantees long-term durability. These chucks are widely used in grinding, EDM, and engraving machines, offering a practical and efficient solution for high-precision tasks.

- 360-degree rotation and adjustable tilt, allowing precise positioning of the workpiece for accurate wire alignment in cutting applications.

- High precision and strong magnetic adhesion, ensuring firm clamping during machining operations.

- Quick and convenient adjustment, facilitating efficient calibration of the cutting wire.

- Suitable for wire cutting machines, improving operational accuracy and workflow efficiency.

| Model | Dimensions (mm) | Holding force (N/cm²) | Weight (kg) | ||

| L | W | H | |||

| SWPC44-155×120 | 155 | 120 | 200 | ≥80 | 16 |

Sine plates with fine particle magnetic chucks are a suitable solution for grinding, EDM, and engraving applications. Their rigid steel construction, combined with high-performance permanent magnets, ensures secure positioning and long-term durability.

- Manufactured with hardened steel for enhanced wear resistance and structural stability.

- Gauge block adjustment enables precise and repeatable angle positioning.

- Parallelism tolerance of 0.005mm/100mm, maintaining high accuracy in machining.

- Available in multiple pole pitches—0.5 1.5mm, 1 3mm, and 0.5 1mm—meeting diverse application needs.

| Model | Dimensions (mm) | Adjustable angle | Weight (kg) | Holding force (N/cm²) | |||||

| L | B | C | D | E | A | ||||

| | 175 | 100 | 86 | 75 | 48 | 255 | 0-60° | 11.5 | 100 |

| | 150 | 150 | 86 | 100 | 48 | 200 | 0-60° | 15 | 100 |

| | 300 | 150 | 86 | 100 | 48 | 350 | 0-60° | 32 | 100 |

| | 250 | 125 | 86 | 75 | 48 | 300 | 0-60° | 19.5 | 100 |

SWPC43

Precision machining often requires complex angular adjustments. Double sine plate permanent magnetic chucks allow for dual-axis tilting, making them ideal for high-precision grinding, EDM, and engraving tasks. Their robust structure and fine pole magnetic system ensure firm clamping and stability during operation.

- Supports front-back and left-right tilting, making it ideal for high-precision angular machining.

- Available in three pole pitch options, 0.5 1.5mm, 1 3mm, and 0.5 1mm, allowing flexibility for different workpiece requirements.

| Model | Dimensions (mm) | Adjustable angle | Weight (kg) | Holding force (N/cm²) | |||||

| L | B | C | D | E | A | ||||

| | 175 | 100 | 86 | 75 | 48 | 255 | 0-60° | 11.5 | 100 |

| | 150 | 150 | 86 | 100 | 48 | 200 | 0-60° | 15 | 100 |

| | 300 | 150 | 86 | 100 | 48 | 350 | 0-60° | 32 | 100 |

| | 250 | 125 | 86 | 75 | 48 | 300 | 0-60° | 19.5 | 100 |

SWPC45

For applications requiring precise angular grinding and wire cutting, the SWPC45 double sine plate permanent magnetic chuck provides a stable and adjustable clamping solution. Its integrated design enhances accuracy and repeatability, making it a reliable choice for high-precision machining.

- Equipped with a graduated scale on the spindle for easy angle adjustments.

- One-piece construction integrates the magnetic chuck and spindle for enhanced stability.

- Consistent surface precision, ensuring no accuracy loss when switching the magnetic force on or off.

- An additional vernier scale improves angle positioning accuracy.

- Available in three pole pitches, 0.5 1.5mm, 1 3mm, and 0.5 1mm, offering flexibility for different workpiece requirements.

| Model | Dimensions (mm) | Weight (kg) | Holding force (N/cm²) | ||||

| B | L1 | H1 | H2 | L2 | |||

| | 125 | 250 | 95 | 145 | 350 | 28.5 | 100 |

| | 150 | 300 | 105 | 160 | 400 | 39.5 | 100 |

| | 150 | 350 | 105 | 160 | 450 | 45.5 | 100 |

| | 150 | 400 | 105 | 160 | 550 | 56.1 | 100 |

Workpieces requiring stable and secure clamping during machining benefit from round permanent magnetic chucks. These chucks are commonly used on lathes, grinding machines, EDM machines, and rotary tables, providing a reliable holding force for various workpieces. For smaller or thinner materials, a fine-pole magnetic chuck can be selected to ensure better stability and precision.

- Three pole pitch options, 0.5 1.5mm, 1 3mm, and 0.5 1mm, offer flexibility for different workpiece sizes and machining requirements.

| Model | Dimensions (mm) | Weight (kg) | Holding force (N/cm²) | |||||

| D | H | K | C | Z | M | |||

| | 125 | 48 | 3 | 80 | 4 | M6 | 4.6 | 100 |

| | 150 | 48 | 3 | 100 | 4 | M6 | 6.6 | 100 |

| | 160 | 48 | 3 | 100 | 4 | M8 | 8.9 | 100 |

| | 200 | 52 | 4 | 120 | 4 | M8 | 12.8 | 100 |

| | 250 | 52 | 4 | 160 | 4 | M8 | 20 | 100 |

| | 300 | 58 | 4 | 220 | 4 | M8 | 32 | 100 |

| | 400 | 58 | 4 | 300 | 4 | M10 | 57 | 100 |

| | 500 | 65 | 5 | 408 | 4 | M12 | 100 | 100 |

| | 600 | 65 | 5 | 528 | 4 | M12 | 144 | 100 |