Billet Sawing System

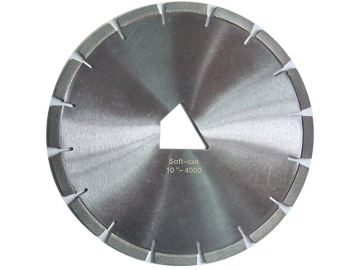

To make it convenient for customers to make aluminum billets in all kinds of specifications, Liancheng offers two types of billet sawing system, i.e. manual billet sawing machine and semi-automatic billet sawing machine.

The billet sawing system can carry out cutting of Ф60-Ф300mm aluminum billets. Purchase cost is relatively low, whereas the operation of the billet saw requires large consumption of labor.

As compared with the manual machine, this aluminum sawing solution can effectively reduce labor strength. Billet feeding is driven by air cylinder. Saw feeding speed is controlled by stepping motor, and it can be adjusted on the touch screen, ensuring high stability and strong cutting capacity.

In auto running condition, the sawing system will conduct continuous feeding, cutting and counting automatically according to preset length. As all the billets are almost finished feeding to the machine, it will warn the operator and then return back the feed sliding plate and stop the machine. Cut workpieces come with vertical end face and precise size.

This metal cutting saw can dramatically reduce labor intensity while at the same time improve safety factor. Moreover, it is designed to allow one person to operate several machines once. It is perfect for cutting cooper and aluminum materials, and has become the ideal equipment for valve and instrument industry. Like the manual one, the automatic billet sawing system can also be used to cut Ф60-Ф300mm aluminum billets.

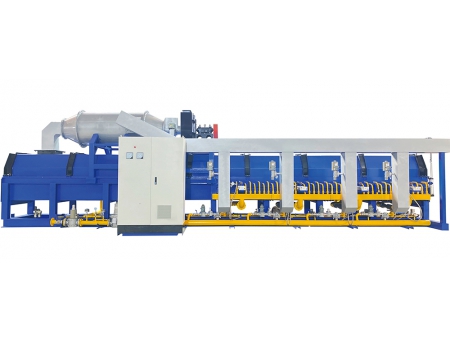

These two types of machines are the auxiliary equipment that we supply for the later process of aluminum foundry equipment. If you want to buy, call us directly. We provide the technical know-how for effective billet production, and we focus on the entire melting and casting process, and guarantee the results of the billets.