Concrete Batching Plant

Over years of continuous improvement, Sanhe's technology in concrete batching plant has been proven and more sophisticated. It comes with higher reliability in operation.

Features

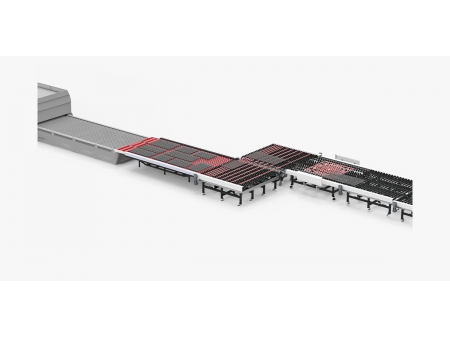

1. Our concrete plant features eco-friendly design. Fully sealed design plus multi-step dust collection unit minimize dust pollution.

2. Modular design enables fast installation.

3. The main batching and mixing system comes in portal frame that ensures great stability. Interior space is reasonably arranged and discharge driveway is wide.

4. Air circuit of the concrete batching plant comes with a two-step filtration system which will extends the life time of pneumatic components.

5. The batch plant is proud of a state of the art radial gate anti-stuck technology for aggregate batching system.

6. Key parts and electrical components of the concrete mixing plant are all from globally renowned suppliers.

7. Ladder, guardrail and electrical protection devices are made in strict accordance with safety standards. This fully presents our design concept-safety first.

| Model | | | | | | |

| Production capacity (m3/h) | 60 | 90 | 120 | 180 | 240 | |

| Mixer | Model | | | | | |

| Power (KW) | 2 x 22 | 2 x 30 | 2 x 37 | 2 x 55 | 2 x 75 | |

| Discharging capacity (m3) | 1 | 1.5 | 2 | 3 | 4 | |

| Aggregate size (mm) | <60 | <80 | <120 | <120 | <120 | |

| Batching system | Volume (m3) | 3 x 13 | 3 x 13 | 3 x 13 | 4 x 20 | 4 x 20 |

| Number of tank | 3 | 3 | 3 | 4 | 4 | |

| Belt conveyor capacity (t/h) | 200 | 200 | 300 | 400 | 600 | |

| Dosing range and accuracy | Aggregate(KG) | 2500±2% | 3500±2% | 4500±2% | 6500±2% | 9000±2% |

| Cement(KG) | 600±1% | 900±1% | 1200±1% | 1800±1% | 2400±1% | |

| Fly ash(KG) | 200±1% | 300±1% | 400±1% | 600±1% | 800±1% | |

| Water(KG) | 300±1% | 400±1% | 600±1% | 800±1% | 1000±1% | |

| Additives(KG) | 10±1% | 30±1% | 30±1% | 50±1% | 50±1% | |

| Total power(KW) | 82 | 108 | 127 | 178 | 220 | |

| Discharge height(M) | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | |