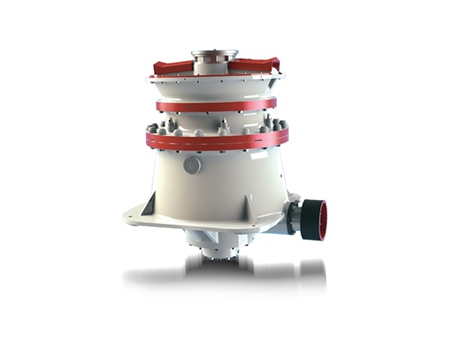

Cone Crusher, S Series

Applications

The S series cone crusher is commonly used to break medium to hard rocks and ores in metallurgy, building and road construction, chemical engineering, and silicate industries. Materials that can be crushed by this crushing equipment include quartz stone, basalt, granite, limestone, marble, dolomite, pyrite, shale, marlstone, gravel, pebbles, etc.

Components

A cone crusher typically comprises a frame, transmission (including bearings, countershaft, countershaft box, and eccentric shaft), bowl liner, mantle liner, head (crushing cone), threaded wedge ring, adjustment ring, and spring, among other associated parts. Copper shaft bushings are used in place of bearings. There are also 8 hydraulic jacks fitted around the crusher exterior.

Features

1. High spinning speed and long stroke result in exceptional productivity.

2. Self-cleaning functionality (hydraulic clearing system) reduces downtime and enables low power consumption.

3. Grease lubricated seal prevents dust and extends lubricant life and parts wear life.

4. The gear, eccentric shaft and other critical parts are precision castings that have been through flaw detection, straightening, quenching and tempering processes.

5. Eight hydraulic jacks ensure the reliability of our cone crusher.

6. Automatic discharge opening size adjustment

7. Spring-type tramp release is provided to pass un-crushable material without disrupting production.

8. Both primary and secondary hydraulic stations are original factory parts for seamless integration into the cone crusher. For countries with cold wintry days, such as in Japan, Korea, Russia, Kazakhstan, Canada, Switzerland, and Norway, a heating device is added to ensure proper functioning of the oil circuit.

| Standard | Crushing Chamber | Min. Discharge Opening (mm) | Power ( kw ) | Capacity(t/h) | ||||||||||||

| Discharge opening (mm) | ||||||||||||||||

| 9 | 13 | 16 | 19 | 22 | 25 | 31 | 38 | 51 | 64 | 76 | 89 | 102 | ||||

| | C | 9 | 75 | 45 | 59 | 72 | 81 | 91 | ||||||||

| M | 13 | 59 | 72 | 91 | 109 | 118 | 136 | 163 | ||||||||

| EF | 25 | 128 | 147 | 175 | 196 | |||||||||||

| | C | 13 | 185 | 109 | 127 | 145 | 154 | 163 | 181 | |||||||

| M | 16 | 132 | 159 | 172 | 200 | 227 | 253 | 309 | ||||||||

| F | 19 | 172 | 195 | 218 | 249 | 295 | 378 | |||||||||

| EF | 25 | 236 | 276 | 324 | 398 | 455 | ||||||||||

| | C | 15 | 240 | 181 | 204 | 227 | 258 | 195 | 327 | |||||||

| M | 22 | 258 | 290 | 336 | 381 | 437 | 437 | |||||||||

| F | 25 | 354 | 417 | 454 | 610 | 610 | ||||||||||

| EF | 38 | 538 | 630 | 743 | ||||||||||||

| | C | 19 | 400 | 381 | 408 | 499 | 617 | 726 | 852 | 1036 | ||||||

| M | 25 | 608 | 726 | 807 | 998 | 1128 | 1296 | |||||||||

| F | 31 | 789 | 844 | 1088 | 1257 | 1386 | 1450 | |||||||||

| EF | 38 | 880 | 1179 | 1361 | 1473 | 1531 | 1643 | |||||||||

| Standard | Crushing Chamber | Min discharge opening (mm) | Power ( kw ) | Capaciey (t/h) | ||||||||||

| Close discharge size(mm) | ||||||||||||||

| 3 | 5 | 6 | 10 | 13 | 16 | 19 | 25 | 29 | 32 | 38 | ||||

| | C | 3 | 75 | 27 | 41 | 54 | 68 | 90 | ||||||

| M | 3 | 27 | 41 | 54 | 38 | 90 | 100 | |||||||

| EF | 6 | 59 | 73 | 95 | 113 | 127 | ||||||||

| | C | 3 | 155 | 36 | 59 | 82 | 104 | 136 | 163 | |||||

| M | 6 | 82 | 104 | 136 | 163 | |||||||||

| F | 8 | 109 | 159 | 181 | 200 | 227 | ||||||||

| EF | 16 | 209 | 236 | |||||||||||

| | C | 5 | 240 | 90 | 136 | 163 | 209 | |||||||

| M | 6 | 136 | 163 | 209 | 253 | 281 | ||||||||

| F | 10 | 190 | 253 | 281 | 308 | 336 | ||||||||

| EF | 13 | 253 | 281 | 308 | 336 | |||||||||

| | C | 5 | 400 | 190 | 270 | 345 | 360 | 408 | 475 | 512 | ||||

| M | 10 | 354 | 408 | 454 | 508 | 560 | 613 | |||||||

| F | 13 | 454 | 480 | 540 | 599 | 661 | 685 | |||||||

| EF | 16 | 508 | 590 | 653 | 680 | 693 | 720 | |||||||