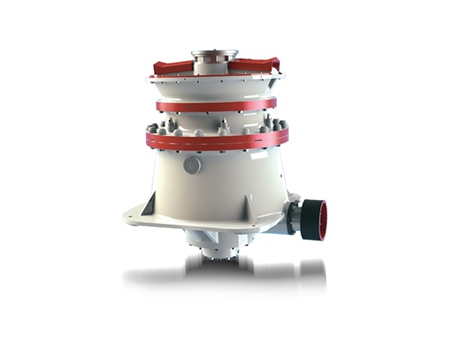

Cone Crusher, SGC Series

Applications

Like many other cone crusher series provided by Yonran, the SGC series crushing equipment is well suited to crushing medium to hard rocks and ores such as quartz stone, basalt, granite, limestone, marble, dolomite, pyrite, shale, marlstone, gravel, pebble, etc. Typical uses for this secondary crusher are in the metallurgy, building and road construction, chemical engineering, and silicate industries.

Components

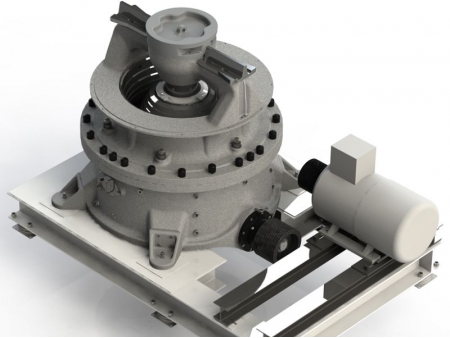

The SGC series cone crusher consists of the frame, transmission (including bearings, countershaft, countershaft box, and eccentric), feed plate, bowl liner, mantle liner, head (crushing cone), adjustment ring, threaded wedge ring assembly, spring, feed distributor, and hydraulic jacks.

Features

1. Unique, state of the art cone design and construction enable steady running and low cost operation.

2. Main frame is of steel castings. Heavy load bearing points are reinforced to withstand great stress.

3. Main shaft has conical roller bearings on both ends. Heavy-duty bevel gears are used for power transmission. Bearings are sealed with skeleton seals to prevent lubricating oil leakage.

4. Hydraulic adjustment mechanism is available for rapid adjustment of the opening size at discharge end.

5. SGC series cone crusher comes standard with hydraulic self-cleaning features. Several hydraulic cylinders, mounted on the base of the main frame, are used to perform self-cleaning.

6. Spring tramp release passes uncrushable material without disrupting production.

7. The oil pump, tank, and lubricating oil supply line are mounted on the exterior of the crusher. When oil temperature or flow speed exceeded the limit, the crusher would automatically shut down.

6. Both primary and secondary hydraulic stations are original factory parts for seamless integration into the cone crusher. For countries with cold wintry days, such as in Japan, Korea, Russia, Kazakhstan, Canada, Switzerland, and Norway, a heating device is added to ensure proper functioning of the oil circuit.

| Model | Chamber | Max. infeed size (MM) | Min. discharge opening (mm) | Motor power (kW) | Capacity(t/h) | Weight (t) | |||||||||

| Closed side opening size(mm) | |||||||||||||||

| 6 | 10 | 13 | 16 | 19 | 22 | 22 | 22 | 22 | 22 | ||||||

| | C | 95 | 10 | 37-45 | 20 | 25 | 30 | 35 | 45 | 50 | 76 | ||||

| M | 72 | 6 | 37-45 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 60 | ||||

| | C | 160 | 13 | 90-110 | 80 | 100 | 135 | 150 | 175 | 235 | |||||

| M | 115 | 10 | 90-110 | 65 | 75 | 90 | 120 | 135 | 150 | ||||||

| F | 80 | 8 | 90-110 | 52 | 62 | 72 | 78 | 115 | |||||||

| EF | 50 | 6 | 90-110 | 50 | 55 | 65 | 70 | 102 | |||||||

| | C | 180 | 13 | 110-132 | 135 | 150 | 180 | 200 | 260 | ||||||

| M | 130 | 10 | 110-132 | 100 | 110 | 120 | 135 | 165 | 175 | ||||||

| F | 90 | 10 | 110-132 | 80 | 105 | 110 | 140 | ||||||||

| EF | 60 | 6 | 110-132 | 60 | 74 | 105 | 110 | 130 | |||||||

| | C | 200 | 16 | 132-160 | 150 | 180 | 200 | 230 | 310 | 390 | |||||

| M | 150 | 13 | 132-160 | 115 | 140 | 160 | 190 | 210 | |||||||

| F | 102 | 10 | 132-160 | 90 | 115 | 145 | 160 | ||||||||

| EF | 70 | 8 | 132-160 | 88 | 110 | 135 | 155 | ||||||||

| | C | 215 | 19 | 185-220 | 200 | 220 | 260 | 350 | 440 | ||||||

| M | 160 | 16 | 185-220 | 155 | 180 | 200 | 220 | ||||||||

| F | 115 | 13 | 185-220 | 150 | 190 | 210 | 230 | ||||||||

| EF | 76 | 8 | 185-220 | 122 | 148 | 185 | 200 | ||||||||

| | C | 235 | 22 | 185-220 | 265 | 310 | 420 | 525 | 580 | ||||||

| M | 175 | 19 | 185-220 | 215 | 240 | 265 | 320 | ||||||||

| F | 130 | 13 | 185-220 | 210 | 235 | 255 | 275 | ||||||||

| EF | 90 | 10 | 185-220 | 148 | 178 | 200 | 220 | ||||||||

| | C | 267 | 22 | 250-300 | 330 | 390 | 525 | 655 | 725 | ||||||

| M | 203 | 16 | 250-300 | 230 | 270 | 300 | 330 | ||||||||

| F | 140 | 13 | 250-300 | 185 | 225 | 265 | 340 | ||||||||

| EF | 95 | 10 | 250-300 | 180 | 220 | 260 | 335 | ||||||||

Note

C=Coarse M=Medium F=Fine EF=Extra Fine

Capacity and minimum discharge opening shown in the above table are based on results obtained from crushing 1.6t/m3 material. Crushing results may vary depending on the feeder configuration, grain size, rock type, and moisture content.