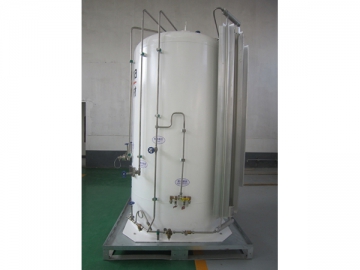

Cryogenic Tank

The cryogenic tank comes standard with the pipeline, base, atomizer, and supercharger, all wrapped up in one single solution that saves you time and money spent on field installation and commissioning. Also known as cryotank, the cryogenic storage tank we sell will be given a trial run before leaving factory.

Bound up in multiple layers of insulations, the cryogenic container is able to maintain a constant low temperature and vacuum level, securing that the contained liquid oxygen or nitrogen is well preserved.

Steel sheets and pipes used in the construction of this cryogenic tank are sourced from well-respected suppliers. Key parts including the gauge, valve, and ferrule are of world-renowned brands. Machining equipment is purchased as a whole rather than in separate parts from abroad. Stringent quality assurance system ensures each cryogenic storage vessel is safe for use, durable, and leak-free.

By leveraging decades of hands-on experience and valuable advice collected from extensive customer surveys, we are able to optimize the pipeline design of our cryogenic tank, providing as standard double gas inlet, double gas outlet, supercharger outlet, overflow valve, and drain valve. These features ensure a constant, uninterrupted field gas supply.

Pipes are connected via welding and ferrule, which reduces the chance of leakage. Upon request, we can add in weighing system, liquid level sensor, pressure sensor, temperature sensor, warming alarm, digital gauge, and remote monitoring system. According to the way gas is supplied at customer site, SINOMA is able to customize a secondary pressure adjusting system.

What we provide is a small cryogenic tank that is mounted on a base, wrapped with multiple layers of insulation, and comes also with liquid filling, supercharging, and atomization features. Popular uses for this cryogenic storage vessel are in hospitals, labs, metallurgy, forging, welding, cutting, and shipbuilding industries. The use of cryotanks is in line with national policy to reduce carbon footprint and save energy. Its future looks glittering.

SINOMA supplies these cryotanks in 1 to 5m3 capacity, rated at 0.8 to 3.4MPa. With a body of S30408 stainless steel construction, this pressure vessel can come with either a S30408 stainless steel or Q345R carbon steel casing. Suitable for storing liquid oxygen, nitrogen, argon, carbon dioxide, and natural gas.

Specs of Cryogenic Tank| Standard | Model | Volume | Dimensions (diameter× height ) mm | Tank weight Kg | Working pressure | Testing pressure | Material |

| GB150.1~4; GB/T18442.1~6 | 1m 3 | Φ1000× 2873 | ~1121 | 1.6MPa | 1.8MPa | Double layer stainless steel | |

| 1m 3 | Φ1000× 2873 | ~1256 | 2.5MPa | 2.6MPa | |||

| 1m 3 | Φ1000× 2873 | ~1360 | 3.4MPa | 3.6MPa | |||

| 2m 3 | Φ1250× 3060 | ~1642 | 1.6MPa | 1.8MPa | Outer layer carbon steel, inner layer stainless steel | ||

| 2m 3 | Φ1250× 3060 | ~1782 | 2.5MPa | 2.6MPa | |||

| 2m 3 | Φ1250× 3060 | ~2080 | 3.4MPa | 3.6MPa | |||

| 3m 3 | Φ1450× 3159 | ~2141 | 1.6MPa | 1.8MPa | |||

| 3m 3 | Φ1450× 3159 | ~2141 | 1.6MPa | 1.8MPa | Double layer stainless steel | ||

| 3m3 | Φ1450× 3159 | ~2494 | 2.5MPa | 2.6MPa | Outer layer carbon steel, inner layer stainless steel | ||

| 3m3 | Φ1450× 3159 | ~2675 | 3.4MPa | 3.6MPa | Outer layer carbon steel, inner layer stainless steel | ||

| 4.99m3 | Φ1850× 3160 | ~3050 | 0.8MPa | 0.88MPa | Outer layer carbon steel, inner layer stainless steel | ||

| 5m3 | Φ1850× 3170 | ~3950 | 1.6MPa | 1.8MPa | Outer layer carbon steel, inner layer stainless steel | ||

| 5m 3 | Φ1850× 3170 | ~4500 | 2.4MPa | 2.6MPa | Outer layer carbon steel, inner layer stainless steel | ||

| 5m 3 | Φ1850× 3170 | ~5200 | 3.4MPa | 3.6MPa | Outer layer carbon steel, inner layer stainless steel |